Choosing between forged and cast engine internals? It’s a question that comes up all the time among enthusiasts. Forged components are definitely stronger and more durable than cast ones.

Upgrading to forged internals really only makes sense if you’re planning to push your engine hard—think big power increases or high RPMs. For daily driving or mild builds, cast parts usually do the job without breaking the bank.

Forged parts handle more heat, pressure, and abuse. That’s why they’re a favorite for boosted or aggressively driven engines.

But they expand more with heat, so you’ll need extra clearance, which sometimes means more noise or fussier installation. Not everyone needs that level of toughness, honestly.

Think about what you want out of your car and how you drive it. If you’re just cruising around, the extra strength might not matter.

But if you’re chasing performance, forged internals can help keep your engine alive under serious stress.

Key Takeaways

- Forged internals are tougher and built for high-stress performance engines.

- Cast parts work fine for daily drivers and moderate upgrades.

- The right choice depends on your goals and how you drive.

Understanding Forged and Cast Internals

When you’re picking engine internals, the material and how it’s made really matter. They affect how your engine deals with stress, heat, and wear.

The differences between forged and cast parts can make or break your build.

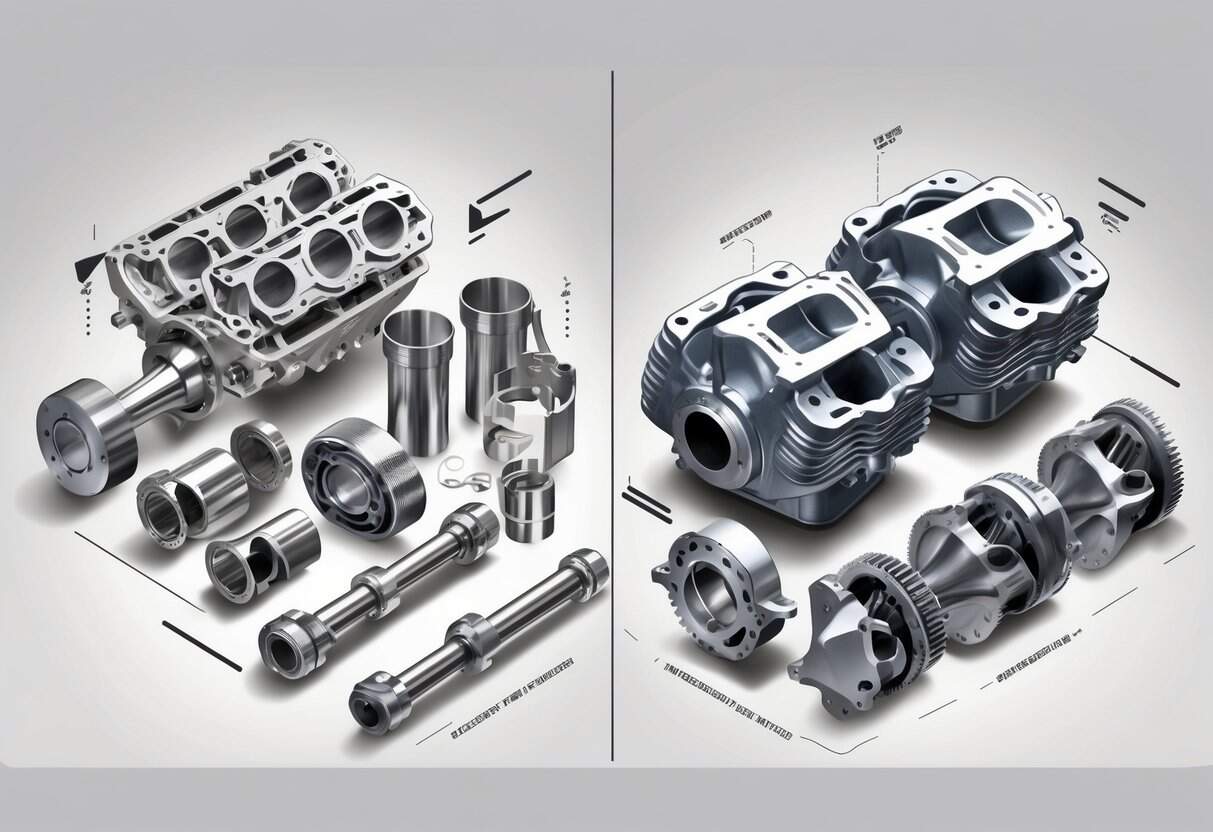

What Are Forged Internals?

Forged internals get shaped by smashing metal under huge pressure, which lines up the grain structure. That gives you parts that are way stronger and less likely to crack under stress.

You’ll spot forged pistons and rods in high-performance or boosted engines. They handle more pressure and heat compared to cast stuff.

But they do need more precise machining and careful fitting, since they expand more when things get hot.

Most forged parts use special aluminum or steel alloys for strength and durability. That usually means they’re lighter and stronger, but not always.

What Are Cast Internals?

Cast internals are made by pouring molten metal into a mold, letting it cool, and popping the part out. It’s cheaper and lets you make more complicated shapes, but the grain structure isn’t as uniform.

Cast iron pistons and rods are typical in stock engines. They’re fine for daily driving and moderate use.

Push them too hard, though—like in racing or heavy boost—and they just don’t have the strength. They can wear out faster or even fail if you go overboard.

Manufacturing Processes and Materials

Forging means smashing metal into shape with a ton of pressure, which lines up the grain and boosts toughness.

Casting is about melting metal, pouring it into a mold, and letting it cool. That creates random grain patterns and sometimes weak spots.

Forged parts often use special aluminum or steel alloys. Cast ones usually go with ductile iron or cast iron, which are easier to work with but not as tough.

Both types need machining after, but forged parts often need a bit more room for heat expansion.

Key Differences in Design and Performance

| Feature | Forged Internals | Cast Internals |

|---|---|---|

| Strength | Higher, more resistant to cracking | Lower, more brittle |

| Weight | Usually lighter | Typically heavier |

| Thermal Expansion | Greater; needs bigger clearances | Less; tighter clearances possible |

| Cost | Higher due to process and finishing | Lower, simpler production |

| Ideal Use | High-stress, high-boost, performance | Daily driving, moderate use |

| Durability | Better under extreme conditions | Good enough for normal driving |

Forged internals are stronger and lighter, handling more power and heat. Cast internals cost less and are best for engines that aren’t pushed too hard.

Performance Benefits and Limitations

Switching to forged internals changes how your engine handles stress, power, and heat. It influences strength, weight, and how well things hold up at high RPMs.

Strength and Durability

Forged internals are pressed into shape under serious pressure, which lines up the metal’s grain. That makes pistons and rods a lot tougher.

They’re less likely to crack or break, especially if you’re running high compression or boost. You’ll get more reliability under tough conditions.

They can be a bit more sensitive to wear if you don’t keep up with maintenance, though. Since they expand differently with heat, you need to get clearances and tuning just right.

Power and High RPM Capabilities

Forged parts can take more stress, so you can safely make more power. They don’t deform as easily at high RPMs.

If you’re tuning for extra horsepower or adding forced induction, forged internals help keep things together. That’s huge if you’re pushing your engine past factory limits.

Cast internals can handle some extra power, but they’ll limit how far you can go. Forged parts give you more room to play without risking disaster.

Weight and Balanced Components

Cast pistons are often lighter, which helps your engine rev quicker and can improve fuel economy. Less weight means less stress on the engine at stock levels.

Forged parts tend to be a bit heavier, so you’ll want to balance everything during assembly to avoid vibration and extra wear.

If you’re chasing big power and reliability, the extra weight of forged internals is usually worth it. But if you just want a quick, responsive daily, cast might be all you need.

Heat Resistance and Cooling Efficiency

Forged internals deal with heat better, thanks to their dense grain structure. They’re less likely to warp or melt, even at higher temps.

That helps keep tolerances tight and reliability up. Some forged pistons even get special coatings to handle heat better.

Cast parts cool faster because they’re less dense, but they can crack if things get too hot. No matter what, a good cooling system is important, especially if you’re running forged parts in a high-performance build.

When Are Forged Upgrades Worth It?

Forged upgrades really matter when your engine faces more stress from extra power, tough conditions, or unique builds. They offer strength and durability where cast parts might just give up.

Forced Induction and High HP Builds

Running a turbo or nitrous? Forged pistons and rods are a must for handling the extra pressure and heat.

More power means more strain on internals. Forged pistons expand more with heat, so you’ll need bigger ring gaps and clearances.

If you’re boosting power by 20% or more, forged internals are a smart investment. They’re especially important if you run a lot of boost or nitrous.

Detonation and High Load Situations

Engines that deal with detonation or high cylinder pressures really benefit from forged parts. Detonation can destroy cast pistons in a hurry.

Forged pistons and rods just handle the abuse better. If you’re tuning for aggressive timing or running high compression, forged internals help avoid expensive failures.

Long highway pulls or heavy throttle? Forged upgrades improve engine life and cut down on the risk of damage from constant stress.

Track, Stroker Kits, and Specialized Applications

If you’re tracking your car or building with a stroker kit, forged pistons and rods are pretty much essential. Stroker kits increase stroke and load on internals.

Pairing a forged crank with forged pistons and rods helps everything survive the extra stress. Track use means high RPMs and quick throttle changes, so you want the best parts.

Special builds like race cars or off-road engines almost always need forged internals. You’re protecting your investment when things get extreme.

Cost, Practicality, and Choosing the Right Parts

Picking between forged and cast internals comes down to cost, durability, and your build goals. Budget, intended use, and engine type all play a part.

Comparing Costs Between Forged and Cast

Forged pistons and rods cost more than cast or hypereutectic versions. That’s because they’re made from tougher alloys and the process is more involved.

Cast pistons and stock rods are cheaper, but they might not last if you’re pushing things hard. Forged pistons resist cracking and handle more pressure, so they’re worth it if you plan to up the power or revs.

Costs can climb if you add balanced cranks or upgraded cams, which often go with forged internals in performance builds.

Longevity and Maintenance

Forged pistons and rods usually last longer, especially in high-RPM or boosted engines. They expand more when hot, so you need bigger piston ring gaps and careful setup, which can mean more maintenance.

Cast parts, like hypereutectic pistons, are more brittle but hold up well under stock conditions. If you keep things close to factory power, they’ll last a good while.

Regularly checking ring lands and cylinder walls is important. Forged parts handle detonation and heat better, so you’re less likely to see sudden failures.

Selecting the Right Internals for Your Engine Build

Pick your parts with your engine’s end goal in mind. For a mild street setup, stock rods and cast or hypereutectic pistons usually make sense—they’re affordable and get the job done.

These work just fine with factory cams and a balanced crank. If you’re thinking about pushing more power, spinning higher RPMs, or swapping in performance heads and ported cams, things change.

At that point, forged pistons and rods are pretty much a must. They’ve got the strength to handle the extra cylinder pressure and help protect your crankshaft and flywheel.

Make sure your pistons and rods actually match your crank, and always balance the whole rotating assembly. Skipping that can lead to annoying vibrations or, worse, early failure.