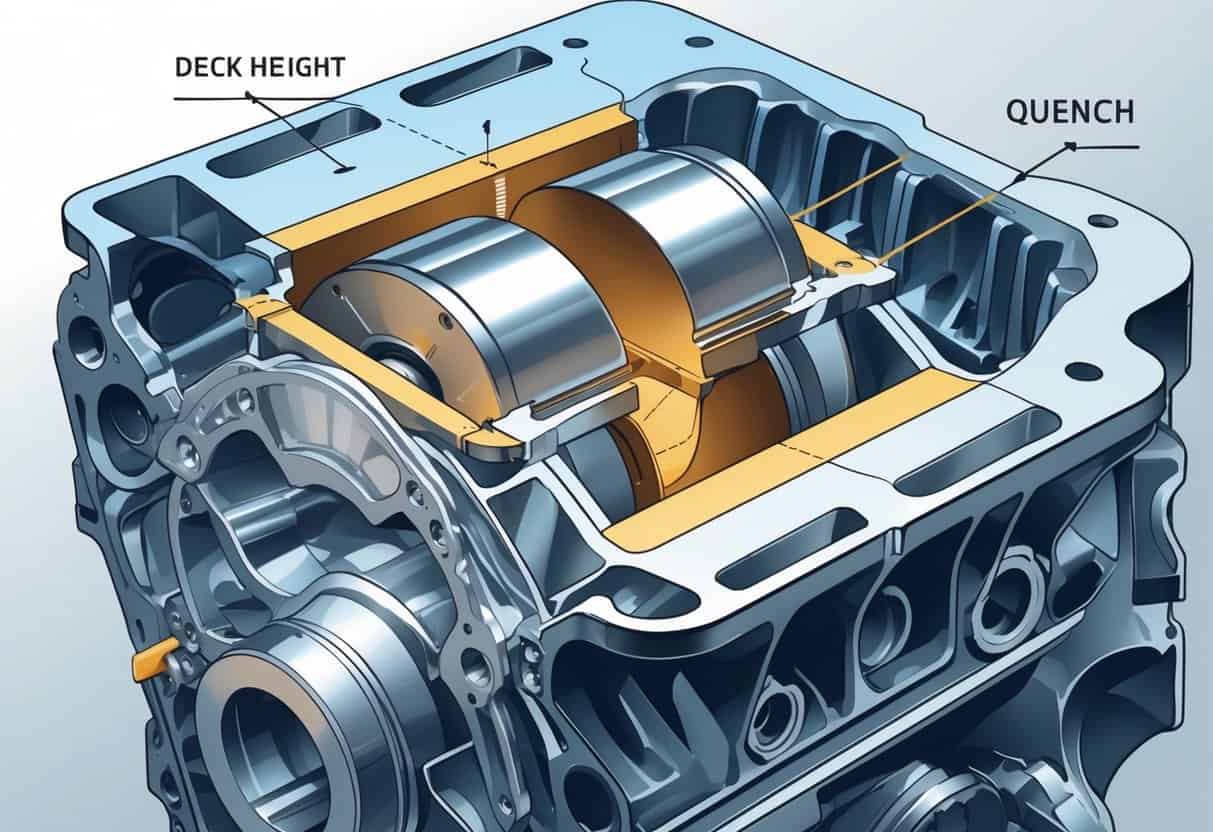

Deck height and quench are two key measurements that shape how your engine performs—and how long it lasts. Deck height is the distance from the crankshaft center to the top surface of the block.

Quench, meanwhile, is the gap between the piston and cylinder head when the piston’s at its highest point. Both need to be dialed in just right to strike a balance between power and reliability.

If deck height is off, the quench area gets thrown out of whack, which messes with combustion efficiency and heat control. Too little quench and parts might smack together; too much, and you lose performance.

You’ve got to find the sweet spot to avoid damage and make the engine run happy.

Key Takeaways

- Proper deck height keeps the piston-to-head distance in check.

- Getting quench right boosts combustion efficiency and keeps the engine safer.

- Tweaking these settings carefully helps you squeeze out more power and reliability.

Understanding Deck Height and Quench

It’s surprising how much the space between your piston and cylinder head can mess with engine performance. Deck height and quench both play into combustion efficiency, power, and how long your engine stays together.

Measuring and controlling these gaps isn’t just for racers—it’s crucial if you want your engine to last.

Defining Deck Height

Deck height is the distance from the top of the engine block’s cylinder to the piston top when it’s at top dead center (TDC). This measurement sets how close the piston gets to the head.

If deck height’s too high, the piston sits further away, and you lose quench effect. Too low, and the piston might tap the head, which is never good.

Most engines run deck heights around .030 to .040 inches from piston to head once assembled. You’ve got to leave some room for things to expand when the engine gets hot.

What is Quench?

Quench is the minimum clearance between the flat part of the piston and the cylinder head at TDC. People also call it piston-to-head clearance or quench distance.

This gap matters for how fuel and air mix and burn. A tighter quench—think .035 to .040 inches—creates turbulence, which speeds up combustion and helps prevent knocking.

If the gap’s too big, you lose those benefits. Too tight, and you risk the piston hitting the head. Getting quench right means your engine runs smoother and lasts longer.

Key Measurements and Terminology

A few terms pop up a lot when talking deck height and quench:

- Deck Height: From cylinder deck surface to piston top at TDC.

- Quench Clearance: The gap between piston flat-top and cylinder head.

- TDC (Top Dead Center): Where the piston’s highest in the cylinder.

- .030/.035/.040: Typical quench distances in inches for performance builds.

The right combo depends on your engine and what you want from it. Always measure with good tools and adjust parts to keep clearances where they need to be.

Critical Role in Engine Performance and Reliability

Deck height and quench aren’t just numbers—they control compression ratios, combustion quality, and how much power you can safely make. These details shape how your engine runs under load and how long it holds up.

Deck Height, Quench, and Compression Ratio

Deck height is the gap between the piston’s top and the block’s deck at TDC. It has a direct effect on the engine’s static compression ratio.

If deck height is off, your compression changes, which tweaks combustion and pressure. Quench is the tiny space between piston head and cylinder head at TDC, and it impacts how well the air-fuel mix compresses and ignites.

A good quench, usually around 0.038 to 0.043 inches for steel rod engines, helps reduce detonation by speeding up and evening out combustion.

Impact on Combustion and Detonation

Combustion quality depends a lot on quench and compression. When quench is tight, the air-fuel mix gets squeezed evenly, which kills off hot spots that can cause knocking.

Engines with the right quench handle detonation better because the flame burns through the chamber quickly and smoothly. If quench is sloppy, you’re more likely to get uneven combustion and damaging pressure spikes.

Effect on Horsepower and Torque

Horsepower and torque come down to how well your engine turns fuel into power. Tight quench and spot-on deck height help combustion burn faster and more completely, which means more cylinder pressure and better throttle response.

Engines with poor quench or mismatched deck height can lose power and need retarded timing to avoid knocking. Getting these right lets you safely run higher compression for more power.

Quench and Engine Heat Load

Quench also plays into heat management. A tighter quench area cools the combustion chamber by speeding up the flame travel.

If the gap’s too big, combustion temps rise, and pistons and heads take more heat. Keeping quench in check helps balance pressure and heat, reducing the risk of overheating or damage—especially if you’re pushing the engine hard.

Optimizing Deck Height and Quench for Power

If you want real-world power and reliability, you’ve got to get deck height and quench working together. This means picking the right head gasket, keeping piston-to-head clearance tight, understanding zero-decking, and matching your parts.

Selecting and Measuring Head Gaskets

Head gasket thickness is a big player in quench and compression. Go for quality brands like Cometic for consistent thickness and durability.

Always measure gasket thickness with a micrometer before bolting it down. Thinner gaskets shrink quench clearance, which can help with combustion, but you need enough thickness to avoid leaks.

Pick a gasket thickness that matches your piston and deck setup—usually around 0.040 inches, but tweak as needed. Double-check for even thickness across the gasket, since unevenness can mess up sealing and quench.

Piston-to-Head Clearance and Quench Distance

Quench distance is the gap between the piston crown and cylinder head at TDC. You want it tight but safe—typically 0.038 to 0.043 inches for steel rods.

A tight quench creates turbulence, speeding up combustion and bumping up power. Too tight, though, and you risk piston-to-head contact.

You can adjust this gap by changing piston design, compression height, gasket thickness, or deck height. Hypereutectic pistons expand differently than forged, so be extra careful with clearances if you use them.

Always measure with the head installed, and don’t forget about piston-to-bore clearance and ring position.

Zero-Decking and Its Benefits

Zero-decking means machining the block so the piston sits flush with the deck at TDC. This minimizes quench and helps combustion finish more completely.

Usually, you’ll need a thinner head gasket and sometimes a dished piston if you want to keep compression under control. This approach tightens up the combustion chamber for more power.

But zero-decking takes precision. If you mess it up, you could blow a head gasket or worse. It works best with forged pistons and aluminum rods that can handle tight clearances and heat.

Material and Component Choices

The pistons and rods you pick matter for deck height and quench. Forged pistons can handle tighter quench than hypereutectic, thanks to better strength and heat tolerance.

Dished pistons drop compression and can give you more clearance if zero-decking isn’t an option. Flat-tops push compression higher but demand more careful setup.

Aluminum rods are lighter but expand more with heat, which changes piston-to-head clearance. Steel rods expand less but add weight.

Match your parts for how they handle heat and stress. Use quality gaskets, the right piston shape, and rods that fit your goals and quench needs.

Practical Considerations in Engine Building

When you’re putting an engine together, managing clearances and matching parts is everything. Whether it’s a street build, a race engine, or something boosted, your deck height and quench choices will change.

A lot of headaches come from skipping measurements or forcing parts that don’t fit.

Achieving Safe and Reliable Clearances

Keep that piston-to-head clearance tight but safe—about 0.035 to 0.043 inches for steel rods and street engines is a solid target. This helps fight off detonation and keeps the piston from smacking the head as things heat up.

Watch your valve clearance and static clearance too. Cam profile and timing affect how much space the valves and pistons need.

Don’t forget piston expansion and pin oiling—you don’t want anything seizing up. If you’re running an automatic or lower RPMs, you can usually go a bit tighter, but always account for piston growth and gasket thickness.

Applications: Street, Racing, and Forced Induction Setups

For street engines on pump gas, a quench around 0.040 inches gives you a good mix of safety and performance. Keeps things stable and avoids detonation.

If you’re building a racing engine or spinning high RPMs, you might run tighter quench for max power, but you’ll need top-notch oil control and cooling.

With forced induction—superchargers, nitrous, whatever—you need more clearance or beefier parts to handle the extra pressure. Too tight a quench here can spell disaster, with piston damage from high cylinder pressures and heat.

Common Mistakes and Troubleshooting

A lot of folks overlook piston-to-head clearance, just assuming a thicker gasket will fix everything. If your rotating assembly sits taller than the deck height, the piston can poke out and hit the head—definitely not what you want.

Skipping a careful check of cam timing and valve overlap is another trap. That kind of oversight can easily wreck valves or pistons.

Running the engine hot, or cranking up spark advance with a lean mixture? You’re flirting with detonation. That usually means knocking sounds or even visible metal damage.

Sure, proper quench helps, but honestly, it won’t save you from bad tuning.

If you’re troubleshooting, look for signs like piston rock, scoring, or burnt valves. Those are red flags that it’s time to rethink your deck height, gasket thickness, or maybe even your cam profile.