When you’re building or upgrading an engine, rod ratio is one of those numbers you really can’t ignore. Rod ratio is the relationship between the length of the connecting rod and the stroke of the crankshaft, and it directly affects how your engine performs.

This simple number influences power output, piston movement, and engine stress.

A higher rod ratio means longer rods compared to stroke, which can cut down on friction and wear inside your engine. Lower ratios, though, can bump up the force on cylinder walls but might give you a little more low-end torque.

Understanding how rod ratio changes engine dynamics helps you pick parts that actually match your goals—whether that’s more power or just keeping things alive longer.

Key Takeways

- Rod ratio links connecting rod length to crankshaft stroke.

- It affects engine efficiency, power, and wear.

- Choosing the right ratio helps balance performance and durability.

Understanding Rod Ratio in Engine Builds

Rod ratio is one of those specs that quietly shapes how your engine acts. It’s about how the connecting rod’s length compares to the crankshaft’s stroke.

This combo affects engine geometry, piston movement, and overall performance in some pretty important ways.

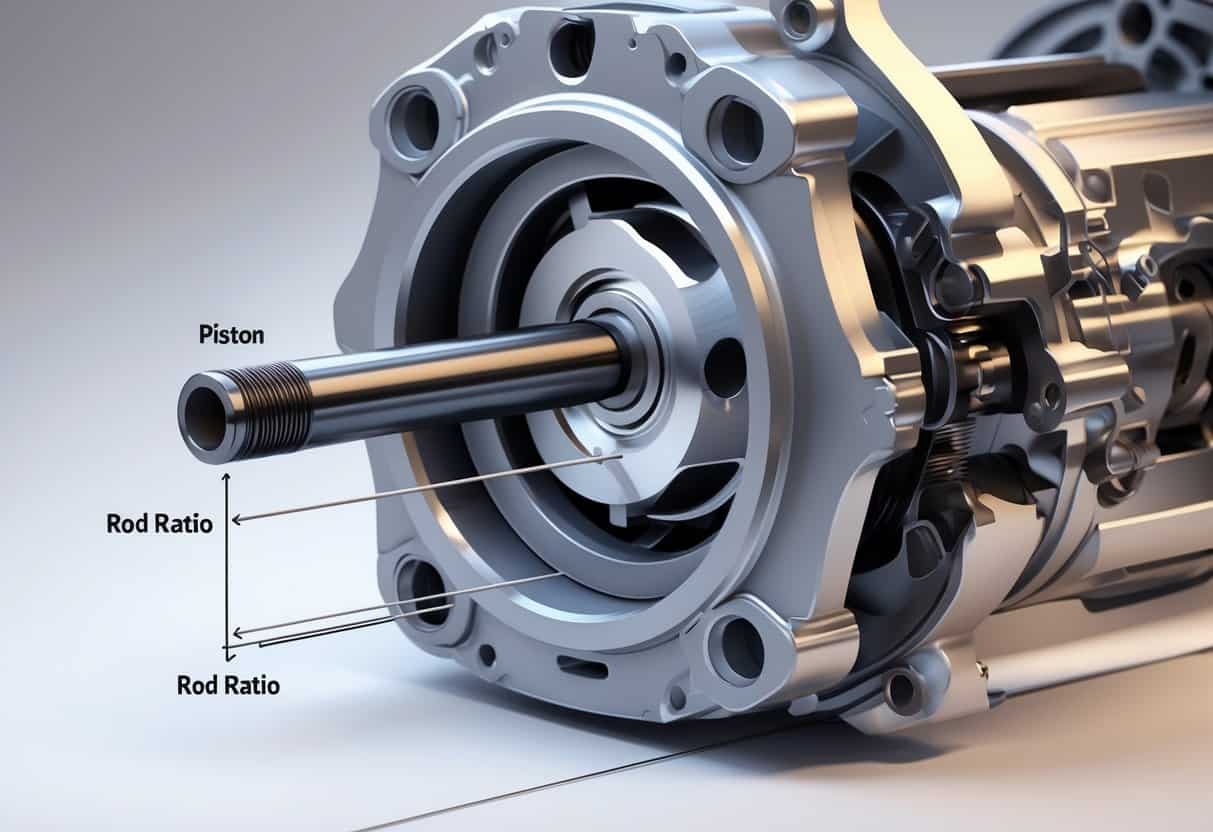

Definition of Rod Ratio

Rod ratio is just the length of the connecting rod divided by the stroke length of the crankshaft. It tells you how long the rod is compared to how far the piston travels up and down.

You get this number by dividing rod length by stroke length. If the rod is longer compared to the stroke, that’s a higher rod ratio.

A lower ratio? Shorter rod compared to the stroke. This ratio shifts the angle between the connecting rod and the crankshaft, which matters for engine wear, efficiency, and how the piston moves inside the cylinder.

How Rod Ratio Is Calculated

Here’s the formula:

Rod Ratio = Rod Length ÷ Stroke Length

- Rod Length is the distance from the center of the crankshaft journal to the center of the piston pin.

- Stroke Length is how far the piston moves from top dead center (TDC) to bottom dead center (BDC).

So, if your rod length is 6 inches and your stroke is 3.5 inches, your rod ratio is about 1.71.

You can usually find these numbers in your engine specs, or you can measure them if you’re hands-on. It’s a simple calculation, but it helps you compare engines or tweak your build.

Rod Ratio vs. Stroke Ratio

Rod ratio and stroke length go hand-in-hand, but they’re not the same thing. Rod ratio is about how the rod length compares to the stroke. Stroke is just the total distance the piston travels.

Rod ratio affects the rod stroke ratio—that’s what influences piston speed, side loading on the cylinder walls, and overall engine geometry.

Higher rod ratios usually mean less sideways force on the piston, which can help reduce wear in the cylinder. It also changes how long the piston hangs around near top dead center (TDC), which can affect combustion.

Lower rod ratios, though, make the connecting rod angle more during crankshaft rotation. That can bump up friction and wear.

Impact of Rod Ratio on Engine Performance

Rod ratio shapes how your engine feels and performs—power delivery, speed, efficiency, all of it. Tweak it, and you shift the balance between torque and horsepower.

It also impacts how well the engine breathes at high rpm and controls piston speed and dwell time, which matters for efficiency.

Effects on Torque and Horsepower

Rod ratio changes the way the piston moves in the cylinder. Higher rod ratios (longer rods relative to stroke) usually lower side forces on the piston.

This can help horsepower, especially as you climb into higher rpm. The piston moves more smoothly.

Lower rod ratios tend to boost torque at lower rpm. The piston accelerates faster, which increases cylinder pressure earlier in the stroke.

It makes the engine feel punchier down low but can add stress to parts.

Here’s a quick look:

| Rod Ratio | Torque Focus | Horsepower Focus |

|---|---|---|

| Low | More low-end torque | Less high rpm hp |

| High | Less low-end torque | More high rpm hp |

Influence on RPM Range and High RPM Breathing

Rod ratio affects how high your engine can safely rev and how it breathes at those speeds. Bigger rod ratios keep the piston steadier near TDC.

That means less friction and stress on pistons and rings at high rpm. With a higher rod ratio, the piston hangs out near TDC a bit longer, which helps combustion and keeps power up high.

If you want an engine that loves the high rpm life, longer rods relative to stroke are usually the way to go. But you might lose a bit of that snappy low-rpm torque.

Piston Speed and Piston Dwell Time

Piston speed depends on stroke and rpm, but rod ratio shapes how the piston accelerates and how long it stays near the top—what they call dwell time.

Longer rods increase dwell time at TDC. That means the piston moves slower around the top, giving the air-fuel mix more time to burn.

This can help combustion efficiency and squeeze out more power. Short rods, though, mean higher piston speeds, which can wear parts out quicker.

That extra speed creates more heat and vibration. So, picking a rod ratio is a balancing act between performance and keeping your engine alive.

Rod Ratio and Efficiency

Your engine’s fuel and mechanical efficiency both hinge on rod ratio. Higher rod ratios cut friction between the piston skirt and the cylinder walls.

Less friction means more of your fuel’s energy turns into power instead of just heating things up. That can boost fuel economy and make the engine run smoother.

Lower rod ratios, on the other hand, increase piston side loading. That ramps up friction and parts wear, so you might be wrenching more often.

Rod Ratio and Engine Longevity

Rod ratio changes the forces inside your engine, which affects how long it’ll last. It tweaks friction, wear, and how hard the parts work together.

Effects on Friction and Side Loading

Rod ratio is just rod length divided by crankshaft stroke. Higher rod ratios mean longer rods compared to stroke.

That lowers side loading—the sideways push of the piston against the cylinder walls. Less side loading means less friction and heat.

Parts move smoother, and your engine stays cooler. That’s good news for piston rings and cylinder walls.

Shorter rods, though, increase side loading. More friction, more heat, and more wear. It’s not great for efficiency or longevity.

Durability and Reliability Factors

Longer rods cut down on the angular movement of the rod as the piston moves. That means less stress on the rod bolts and pins, so you get better durability.

Less angularity also means a lower risk of rod bending or bearing failure. Plus, longer rods reduce piston acceleration and deceleration forces.

That lowers the risk of piston slap and eases the load on the wrist pin and piston crown. Your engine is more likely to stay reliable, especially if you’re revving it high.

But if the rod gets too long, your engine might get bigger and heavier. That can hurt responsiveness, depending on your goals.

Influence on Engine Wear and Cylinder Walls

Rod ratio also shapes how the piston rubs against the cylinder walls. Higher ratios keep the piston more upright, so pressure on the cylinders is more even.

That means less weird wear patterns and better ring sealing. Lower rod ratios, though, increase side loading and push the piston harder against one side.

You end up with uneven wear and a bigger risk of scuffing or scoring. The right rod ratio keeps these stresses in check and helps your cylinders stay healthy.

Choosing the Right Rod Ratio for Your Build

Picking the right rod ratio depends on what you want your engine to do, your stroke length, and even the materials you’re using. Rod length changes engine speed, torque, and how long it’ll last.

You’ll also want to think about cost and what kind of moving parts your build needs.

Long Rods vs. Short Rods

Long rods usually mean less piston side loading. That helps reduce cylinder wear and makes the engine smoother.

You might get a broader power band in the mid and high rpm range. Long rods fit well with short stroke engines and tall deck blocks.

Short rods, though, make the piston move quicker. That can help with low-speed torque, so they’re common in stroker engines with long strokes and tight spaces.

But more side loading means more friction and faster wear. Pick your rod length based on your engine’s layout and what you want it to do.

Application Considerations: Racing, Street, and Marine

What your engine’s for really matters here. Racing engines often go for higher rod ratios and long rods for high rpm stability and power.

Drag racers, though, want short, tough rods that can handle brutal launches. For street engines, a balanced rod ratio gives you good torque and reliable power across the whole rpm range.

Marine engines need rods that can handle long hours and harsh conditions, so corrosion-resistant materials are a must.

Material Choices: Steel, Aluminum, and Titanium Connecting Rods

Steel rods are the classic choice—strong, affordable, and reliable. They can handle big loads but are a bit heavy, which might limit rpm in racing.

Aluminum rods are lighter and great for high rpm, but they wear out faster and usually need replacing after a while.

Titanium rods are super light and strong, but the price is wild. You’ll mostly see them in pro-level race engines where every ounce and rpm counts.

Budget, Strokers, and Build Types

Your budget really sets the stage for what you can do with material and rod length. Steel connecting rods are usually the go-to choice for most street builds since they’re easy on the wallet.

Aluminum and titanium rods? Well, they’re pricier, but they can make your engine feel snappier and help with power at higher RPMs. Not everyone needs that, but it’s tempting.

Now, for stroker builds, long rods can be tricky. They often won’t fit unless you’ve got a tall deck block or you’re willing to splurge on custom pistons.

If you’re working with a standard engine block or just trying not to break the bank, you might be stuck with shorter rods. It’s not the end of the world, but it’s something to keep in mind.

Here’s a quick list of things you’ll want to think about:

- Rod length: Affects piston speed and the side load on the cylinder wall

- Rod ratio: Longer rods are better for high RPM; shorter rods give you more torque

- Material: Steel is solid for budget and durability, aluminum is lighter for racing, titanium if you want to go all-out

- Engine type: Whether it’s for racing, street, or even marine use, each one changes what rods make sense

- Block size: If you’ve got a taller block, you can run longer rods in stroker setups