Table of Contents

Exhaust Heat Management in Vehicles: Techniques for Performance & Efficiency

Introduction

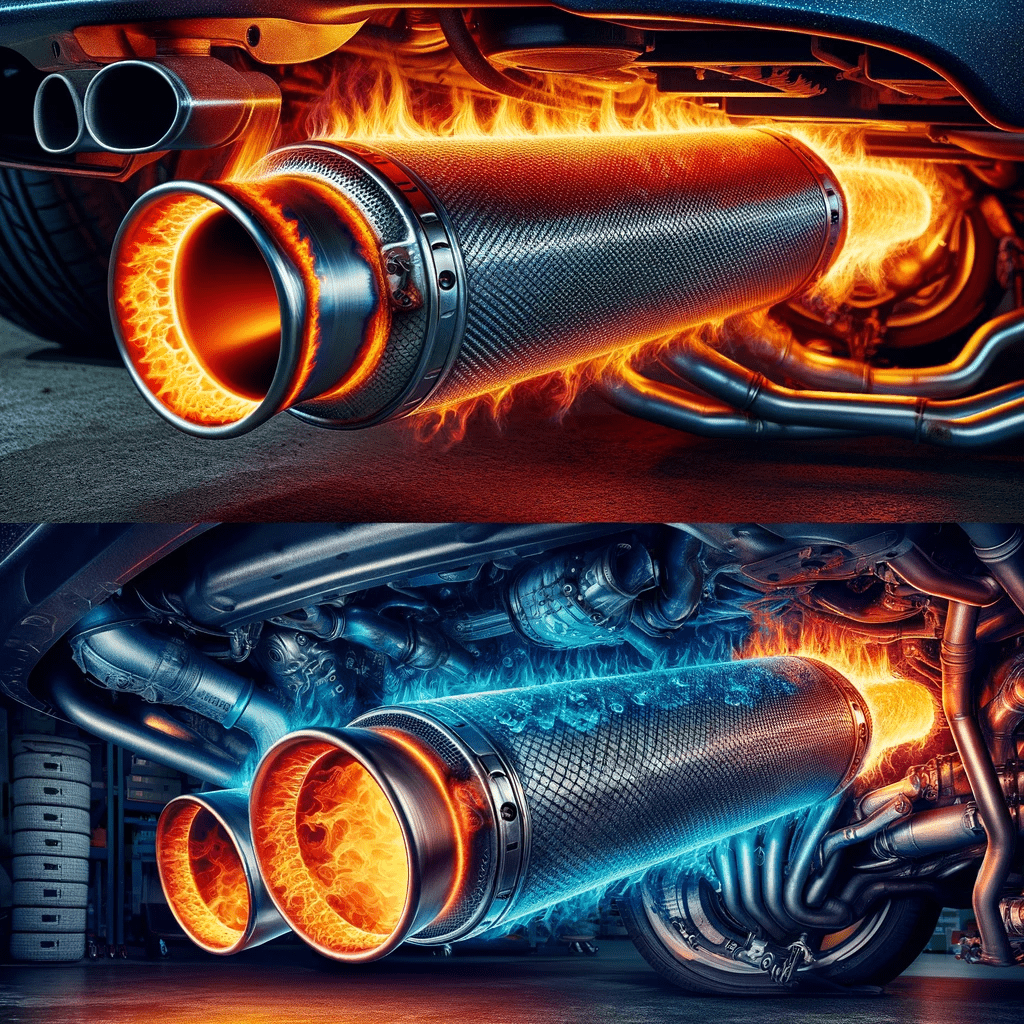

Proper exhaust heat management is essential for enhancing vehicle performance, protecting critical components, and improving overall efficiency. As engines become more powerful and emissions regulations tighten, controlling exhaust temperatures is more crucial than ever.

This guide explores the latest heat management techniques, including heat shields, ceramic coatings, exhaust wraps, and advanced materials, ensuring that your exhaust system performs optimally while maintaining durability.

Key Takeaways: Importance of Exhaust Heat Management

| Aspect | Importance |

|---|---|

| Heat Reduction | Prevents damage to nearby components and improves overall performance |

| Heat Shields | Deflects heat from sensitive parts like wiring, fuel lines, and interiors |

| Ceramic Coatings | Lowers surface temperatures, increasing part longevity |

| Exhaust Wraps | Maintains exhaust gas temperatures to improve efficiency |

| Material Choices | High-temperature-resistant materials ensure long-term durability |

Understanding Exhaust Heat Management

1. Reducing Excessive Heat: Why It Matters

Excess heat from the exhaust system can cause significant damage to surrounding components, leading to:

- Warped body panels and damaged paint

- Melted wiring or fuel lines

- Reduced engine efficiency due to excessive heat soak

Managing exhaust temperatures correctly ensures:

✅ Better engine efficiency

✅ Longer-lasting components

✅ Improved safety and reliability

2. Heat Shields: Deflecting and Absorbing Heat

Heat shields are strategically placed barriers designed to deflect and absorb heat from the exhaust system.

Types of Heat Shields:

- Rigid Metal Shields – Typically made from stainless steel or aluminum, used to protect sensitive engine bay components.

- Reflective Thermal Barriers – Designed with ceramic or fiberglass layers to reflect radiant heat away from parts like fuel tanks and interiors.

- Flexible Heat Wraps – Used in tight spaces where rigid shields won’t fit.

Best for: Performance vehicles and exhaust system upgrades where high heat is concentrated in a small area.

3. Ceramic Coatings: Heat Protection & Performance Boost

Ceramic coatings are applied directly to exhaust manifolds, headers, and pipes to reduce heat radiation and increase performance.

Advantages of Ceramic Coatings:

✅ Lower surface temperatures – Reduces heat transfer to the engine bay.

✅ Longer component life – Protects against corrosion and thermal fatigue.

✅ Better exhaust gas velocity – Maintains heat inside the pipes, improving exhaust scavenging.

✅ Improved aesthetics – Provides a sleek, durable finish that resists discoloration.

Best for: High-performance and turbocharged vehicles where heat control is critical.

4. Exhaust Wraps: Maintaining Exhaust Gas Temperature

Exhaust wraps are thermal insulation materials wrapped around headers and downpipes to keep heat inside the exhaust system.

How Exhaust Wraps Help Performance:

- Reduces under-hood temperatures, preventing heat soak in surrounding components.

- Maintains exhaust gas velocity, improving turbo spool time and overall efficiency.

- Prevents burns and heat damage to nearby wires and hoses.

Materials Used:

- Fiberglass-based wraps – Most common and budget-friendly.

- Titanium-based wraps – Withstand higher temperatures, ideal for turbo applications.

- Silica or basalt fiber wraps – Offer superior heat insulation and durability.

Best for: Turbocharged or supercharged vehicles where heat buildup is a concern.

5. Material Choices for Exhaust Heat Management

The material used in an exhaust system plays a significant role in heat resistance and durability.

| Material | Key Benefits | Application |

|---|---|---|

| Stainless Steel | Excellent heat resistance, corrosion-resistant | Performance exhausts, headers |

| Titanium | Ultra-lightweight, superior heat dissipation | High-end sports cars, race cars |

| Ceramic-Coated Steel | Reduces surface temps, increases longevity | Aftermarket headers, turbo manifolds |

| Carbon Fiber Heat Shields | Lightweight, high heat resistance | Luxury & high-performance applications |

Best for: Performance vehicles needing lightweight materials with high heat resistance.

Real-World Applications of Exhaust Heat Management

Performance & Racing Vehicles

- Heat management is critical in high-performance racing to ensure consistent power output and prevent engine bay overheating.

Daily Drivers & Commuters

- Managing exhaust heat prevents early wear on wiring, hoses, and body panels, ensuring long-term vehicle reliability.

Turbocharged & Supercharged Cars

- Turbochargers generate extreme exhaust temperatures, requiring heat shielding, ceramic coatings, and exhaust wraps to prevent heat damage.

Off-Road & Overlanding Vehicles

- Keeping exhaust heat controlled is crucial for reducing cabin heat buildup and protecting drivetrain components during long trips.

Exhaust Heat Management Techniques & Their Applications

| Technique | Function | Application | Benefits |

|---|---|---|---|

| Heat Shields | Reflect and absorb heat | Used in all vehicles, especially performance models | Protects adjacent components |

| Ceramic Coatings | Reduce surface temperatures | Ideal for high-performance, turbocharged, and racing vehicles | Enhances longevity, reduces heat transfer |

| Exhaust Wraps | Insulate exhaust pipes | Best for tight engine bays & turbocharged setups | Reduces under-hood temperatures |

| High-Temperature Paints | Provide heat-resistant coating | Used on headers, manifolds, and exhaust pipes | Protects against rust, reduces radiated heat |

| Titanium Exhaust Systems | Lightweight & high heat resistance | High-end performance and race cars | Reduces overall weight, excellent heat dissipation |

Conclusion: Keeping Exhaust Temperatures in Check

Exhaust heat management is not just for performance cars—it affects the longevity, safety, and efficiency of all vehicles. Whether through heat shields, ceramic coatings, exhaust wraps, or high-performance materials, managing exhaust heat properly can prevent costly damage, enhance efficiency, and improve overall vehicle performance.

If you’re considering exhaust system upgrades, ensure that your setup includes proper heat management techniques to maximize power and durability.

What’s your preferred method of managing exhaust heat? Let us know in the comments!

Additional Resources

Check out the best performance car gear available on the market.