If you’re getting into high-performance electric vehicle (EV) builds, you’ll want to get a handle on how inverters and controllers do their thing. EV inverters take your battery’s direct current (DC) and flip it into alternating current (AC) for the motor, while controllers keep the power flow steady and smart for top performance. These two work in tandem to give you that smooth, punchy power delivery that makes a real difference in performance EVs.

Your EV’s performance really hinges on how well the inverter and controller “talk” to each other and react to what you’re doing behind the wheel. They’re responsible for torque, speed, and how the motor behaves moment-to-moment, so you get precise acceleration and sharp handling.

Whether you’re running a single motor or multiple, these electronic brains are what let you safely wring out every bit of power your build can offer.

Choosing the right inverter and controller combo is a big deal, especially if you want quicker response and better efficiency. If you understand how they work, you can dial in your setup for max power and buttery-smooth operation.

Key Takeways

- Inverters change DC power to AC power for the motor.

- Controllers regulate power flow to optimize motor performance.

- Precise control of power affects acceleration and handling.

Fundamentals of EV Inverters and Controllers

Getting power conversion and control right is crucial if you want your EV to perform. It’s really about knowing how electricity shifts forms and how these parts mesh to drive the motor efficiently.

If you know the basics, you’re better equipped to tweak or pick the right system for your build.

Understanding Power Conversion

Your EV’s battery holds energy as DC. Most performance motors prefer AC—it’s just more efficient and gives you finer control.

The inverter’s main gig is to convert DC from the battery into AC for the motor.

This lets you change motor speed and torque easily by tweaking the frequency and strength of the AC. If you skipped this step, your motor would probably struggle or even get toasted.

Some inverters even handle sending power back to the battery during braking, which helps you recapture energy instead of wasting it.

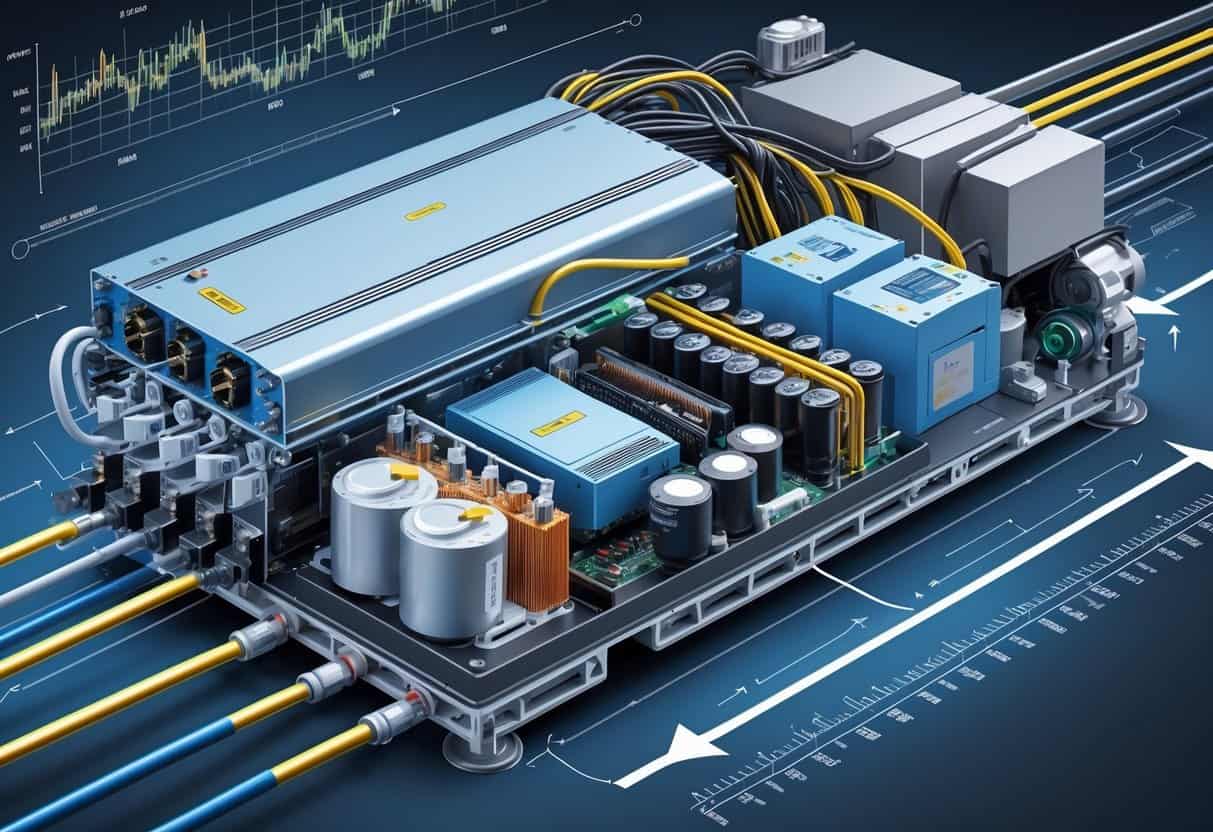

Key Components and Operation

Inside every inverter are power electronics—think transistors and switches—chopping up DC and turning it into AC.

The controller works right alongside, regulating the motor’s speed and torque by reading your throttle input and sensors in the motor. It’s a feedback loop that keeps things smooth, even when you push the limits.

Inverters and controllers need to safely wrangle high currents and voltages, especially if you’re chasing big numbers. They’re also your first line of defense against overheating and electrical mishaps.

Role of Inverters in Performance Builds

In a performance build, the inverter isn’t just a converter—it’s at the heart of how your car puts down power. It decides exactly how much juice hits the motor, so you can push harder without frying anything.

A solid traction inverter means snappier throttle response and sharper acceleration. You can even tweak inverter settings for more torque or higher top speeds, depending on what you’re after.

Performance motors usually run hotter and harder, so your inverter has to be tough, efficient, and able to keep its cool. That’s what lets your EV handle spirited driving without falling apart.

Advanced Technologies and Materials

There’s a bunch of new tech and materials making EV inverters and controllers better. Stuff like advanced semiconductors, smarter gate drivers, and clever ways to cram more power into smaller spaces—all while keeping heat and losses in check.

Understanding these can help you squeeze more efficiency and power out of your build.

Silicon Carbide and IGBT in Inverter Design

Silicon Carbide (SiC) and Insulated Gate Bipolar Transistors (IGBTs) are both big deals in modern inverter design. SiC parts have lower losses and handle heat better than old-school silicon IGBTs.

This means you can run them faster and hotter without cooking the electronics.

IGBTs are still popular for high-current setups—they’re tough and less expensive. But SiC is king when you need high efficiency and quick switching at higher voltages.

Sometimes you’ll see hybrid designs that use both, striking a balance between performance and cost.

Isolated Gate Drivers and Capacitive Isolation

Isolated gate drivers are what keep your control electronics safe from the high-voltage side of things. They use capacitive isolation to keep the noisy, high-powered inverter bits away from your sensitive controller hardware.

Capacitive isolation lets signals zip through fast while blocking nasty voltage spikes. That means fewer false signals and better reliability.

Having isolated gate drivers is pretty much a must for keeping your system safe and letting you control each switch precisely—even when you’re really pushing the hardware.

Impact of High Power Density

High power density is all about packing more punch into a smaller, lighter box. That’s good news for acceleration and range, since every kilo counts.

To get there, you need materials and designs that handle heat and reduce losses. SiC comes up again here, since it doesn’t sweat the heat and can run at higher frequencies.

But, cramming more power into a tiny space brings its own headaches—mainly heat and electromagnetic noise. You’ll need solid cooling and good shielding to keep things running smooth.

High power density pushes your hardware to the edge, but it’s how you get serious power from a compact package.

Performance Factors in EV Powertrains

A lot goes into how your EV’s powertrain performs. It’s not just about raw power—it’s about how efficiently you turn battery juice into motion, manage heat, keep things reliable, and make sure everything plays nice together.

Efficiency and Acceleration

The inverter’s job is to turn battery DC into motor AC, controlling speed and torque on the fly. For hard launches, you want an inverter that delivers power fast and doesn’t waste much energy.

If your system’s efficient, you lose less energy as heat, which helps your range too. Smarter control strategies—like predictive torque control—can squeeze out more acceleration without gobbling up extra battery.

Your traction inverter is front and center here. If you sacrifice efficiency for speed, you might get quick launches but drain your battery faster. It’s a balancing act, especially if you care about both speed and range.

Thermal Management and Cooling Systems

Push your powertrain hard and it’ll get hot—no surprise there. If you don’t keep things cool, you risk damage or losing performance.

Most setups use liquid or air cooling to keep inverters and motors at reasonable temps. Good thermal management means you can drive harder for longer without things shutting down or throttling back.

Overheating is a killer for efficiency and can cap your peak performance, especially if you’re driving aggressively or for extended periods.

Diagnostics, Durability, and Reliability

Keeping tabs on your powertrain’s health is non-negotiable. Diagnostic tools help you spot problems early and tweak settings to keep things running strong.

Reliability comes down to good parts and smart design. Your inverter and controller have to handle heavy loads day in and day out.

Durability means your EV can take a beating—hard launches, long trips, you name it—without falling flat. Diagnostics give you a heads-up before things go sideways.

Integration With Battery Packs and DC/DC Converters

Your inverter and controller need to work hand-in-hand with the battery pack and DC/DC converters. The high-voltage battery feeds the system, and the controller manages how energy flows.

DC/DC converters step voltage up or down for different parts of the car. Getting this integration right means you use energy wisely and get snappy response when you stomp the pedal.

Battery management systems also work with the inverter, protecting the battery and making sure performance stays consistent over time.

Control Systems, Safety, and Real-Time Operation

You’re counting on precise control systems in the inverter to manage power and keep things safe. These systems use real-time data and safety checks to handle stuff like regenerative braking, all while protecting your gear from faults.

Real-Time Control and Microcontrollers

Your inverter leans on microcontrollers to keep motor speed and torque dialed in, moment by moment. These chips chew through sensor data fast, tweaking current and voltage as you drive.

Real-time control means your EV reacts instantly to changes—smooth acceleration, quick power delivery, and efficient battery use. Microcontrollers also juggle the power switches inside the inverter, controlling IGBTs or MOSFETs to turn DC into the AC your motor craves.

Timing is everything here. If it’s off, you lose power or risk overheating.

Functionality in Regenerative Braking and Energy Flow

Regenerative braking is a neat trick—your motor flips from using power to making it, sending energy back to the battery as you slow down.

The inverter’s control system has to manage this swap carefully, so you don’t overcharge or waste energy. It adjusts how fast energy flows based on your battery’s needs.

Managing energy flow is about keeping everything balanced—motor, battery, transmission—so your EV stays smooth whether you’re speeding up, slowing down, or just cruising.

Functional Safety and Health Monitoring

Your EV’s control system has built-in safety features to help protect the motor, inverter, and battery from things like short circuits or overheating.

Most of the time, these systems aim for ASIL D standards, which is basically the highest level of safety in the automotive world.

Health monitoring is always on, checking parts for wear or failure.

It keeps an eye on temperature, voltage, current, and other important metrics, all in real time.

If something looks off, the control system can cut power or safely shut down certain parts to avoid bigger problems.