Table of Contents

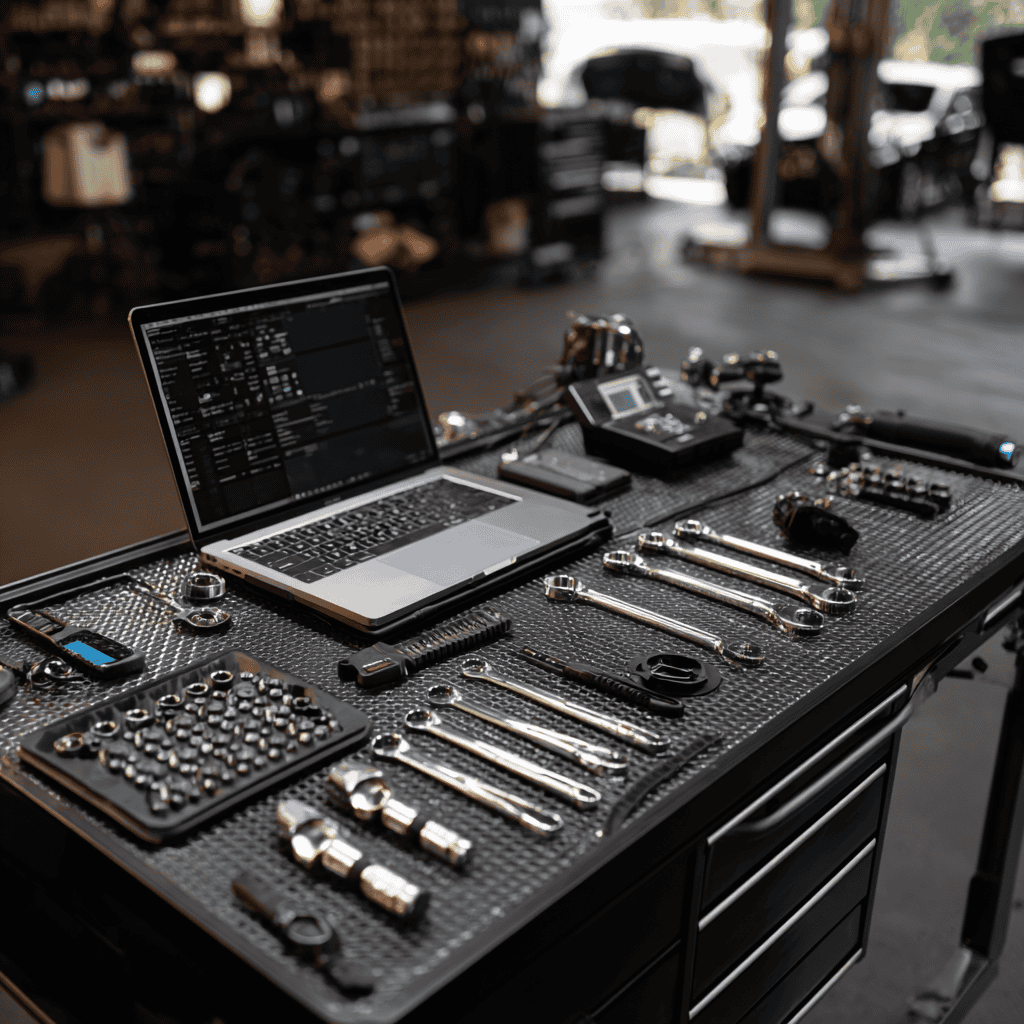

Must-Have Tools for DIY Tuners: Essential for Precision and Efficiency

If you’re serious about dialing in your car’s performance at home, having the right tools isn’t just helpful—it’s absolutely essential. Whether you’re a weekend warrior looking to squeeze more power from your daily driver or an experienced garage tuner building something special, your tool collection directly impacts the quality, safety, and efficiency of your work.

The difference between professional-grade results and backyard hackery often comes down to one thing: having and using the proper equipment. Without it, you’ll find yourself frustrated, wasting valuable time, and potentially causing expensive damage that could have been easily avoided.

Why the Right Tuning Tools Matter More Than You Think

Modern car tuning has evolved far beyond simply bolting on aftermarket parts and hoping for the best. Today’s vehicles are complex systems where mechanical, electrical, and software components must work in perfect harmony. A single parameter out of spec can mean the difference between a reliable performance machine and an expensive paperweight.

Think about it this way: You wouldn’t perform surgery with kitchen utensils, and you shouldn’t attempt precision automotive work with inadequate tools. The right equipment allows you to:

- Diagnose problems accurately before they become catastrophic failures

- Measure performance gains with scientific precision rather than seat-of-the-pants guessing

- Make adjustments safely without risking engine damage

- Save time and money by doing the job right the first time

- Build confidence in your modifications and repairs

Beyond the practical benefits, having proper tools transforms garage tuning from a frustrating struggle into an enjoyable, rewarding hobby. When you can quickly identify issues, make precise adjustments, and verify your results, the entire process becomes more satisfying and productive.

Essential Diagnostic Tools Every Garage Tuner Needs

Before you can improve performance, you need to understand what’s happening under the hood. Diagnostic tools give you a window into your engine’s operation, revealing problems that would otherwise remain hidden until they cause serious damage.

OBD-II Scanners: Your Digital Detective

An OBD-II scanner is arguably the most important diagnostic tool in any modern garage. Since 1996, every car sold in the United States has been required to have an OBD-II port, making these scanners universally useful for garage tuners working on relatively modern vehicles.

These devices do much more than just read check engine codes. A quality scanner provides:

- Real-time data streaming of engine parameters like coolant temperature, intake air temperature, mass airflow sensor readings, and oxygen sensor voltages

- Freeze frame data that captures engine conditions at the moment a fault code was triggered

- Readiness monitors showing whether your vehicle’s emissions systems are functioning properly

- Advanced diagnostics including ABS, transmission, and body control module scanning (on higher-end units)

When shopping for an OBD-II scanner, consider your skill level and budget. Entry-level code readers start around $30 and handle basic fault codes. Mid-range scanners ($100-$300) add live data and more extensive code libraries. Professional-grade tools ($500+) offer manufacturer-specific diagnostics, bi-directional controls, and programming capabilities.

Pro tip: Look for scanners that offer free lifetime updates. Automotive technology evolves constantly, and yesterday’s top-tier scanner becomes obsolete quickly without regular software updates.

Compression Testers: Checking Your Engine’s Heart

A compression tester reveals the mechanical health of your engine by measuring cylinder pressure during the compression stroke. This simple tool can diagnose numerous problems that affect performance:

- Worn piston rings allowing blow-by

- Burned or bent valves failing to seal properly

- Head gasket failures causing compression loss

- Cracked cylinder walls or pistons

- Incorrect valve timing from stretched timing chains or jumped timing belts

Testing compression is straightforward but requires attention to detail. You’ll need to:

- Warm the engine to operating temperature

- Disable the fuel and ignition systems

- Remove all spark plugs

- Thread the compression tester into each cylinder

- Crank the engine through several compression strokes

- Record and compare readings across all cylinders

Healthy engines typically show 150-200 PSI per cylinder, with no more than 10% variance between cylinders. Low readings indicate problems, while significant differences between cylinders point to specific issues requiring attention.

Quality compression testers include multiple adapters for different spark plug thread sizes, a pressure release valve for accurate readings, and a gauge that holds peak pressure. Expect to spend $30-$100 for a reliable kit that will last years.

Vacuum Gauges: Reading Between the Lines

While seemingly simple, a vacuum gauge provides sophisticated insights into engine condition and performance. By measuring manifold vacuum, you can diagnose issues that other tools might miss:

- Vacuum leaks causing lean conditions and rough idle

- Exhaust restrictions from clogged catalytic converters or collapsed pipes

- Valve timing problems affecting engine efficiency

- Ring and valve seal degradation

- Ignition timing issues

Reading a vacuum gauge requires understanding normal patterns. At sea level, a healthy engine typically pulls 17-22 inches of mercury (inHg) at idle. The needle should be steady—bouncing or fluctuating readings indicate specific problems:

- Rhythmic bouncing often points to valve issues

- Gradual drift suggests vacuum leaks

- Low steady readings might indicate late valve timing

- Rapid vibration can mean worn valve guides

Digital vacuum gauges offer precise readings and data logging capabilities, while analog gauges remain popular for their instant visual feedback. Either type costs between $20-$60, making this one of the most cost-effective diagnostic tools available.

Performance Tuning Equipment for Serious Results

Once you’ve diagnosed any issues, it’s time to focus on performance enhancement. These tools help you measure improvements, optimize settings, and ensure modifications deliver real gains rather than just noise.

Dynamometers: Proving Your Power

Nothing validates performance modifications like dyno testing. A dynamometer measures actual power and torque output, providing concrete data about how changes affect performance. Without dyno testing, you’re essentially guessing whether modifications help or hurt.

Two main types serve garage tuners:

Chassis Dynamometers measure power at the wheels, accounting for drivetrain losses. They’re more practical for most tuners since you test the complete vehicle without removing the engine. Modern chassis dynos offer:

- Inertia or load-based testing modes

- Weather correction for consistent results

- Data logging for detailed analysis

- Simulation of real-world driving conditions

Engine Dynamometers test engines outside the vehicle, measuring crankshaft output directly. While more accurate for pure engine power, they’re typically limited to professional engine builders and race teams.

Dyno testing reveals crucial information:

- Power and torque curves showing where engines make power

- Air/fuel ratios throughout the RPM range

- Before/after comparisons validating modifications

- Problem areas where power drops unexpectedly

While owning a dyno is unrealistic for most garage tuners (prices start around $15,000), renting dyno time typically costs $75-$150 per hour. Many performance shops offer dyno days where multiple enthusiasts share costs, making regular testing more affordable.

Engine Management Systems: Taking Control

Modern engine management systems (EMS) put unprecedented control in tuners’ hands. Whether using factory ECU tuning software or standalone systems, these tools let you optimize every aspect of engine operation:

Factory ECU Tuning modifies existing engine computers using specialized software:

- HP Tuners covers GM, Ford, and Chrysler applications

- EcuTek specializes in Subaru, Nissan, and European brands

- Cobb Accessport offers user-friendly tuning for popular performance platforms

- Open-source options like RomRaider provide free alternatives for certain vehicles

Standalone Engine Management replaces factory computers entirely:

- Haltech, AEM, and MoTeC offer professional-grade systems

- MegaSquirt provides DIY-friendly options for budget builds

- FuelTech combines EMS with data logging and traction control

Key parameters you’ll adjust include:

- Fuel maps optimizing air/fuel ratios across all conditions

- Ignition timing maximizing power while preventing detonation

- Boost control for turbocharged applications

- Variable valve timing on equipped engines

- Rev limiters and launch control settings

Learning engine management takes dedication, but the payoff is enormous. Start with conservative changes, use wideband oxygen sensors to monitor results, and always keep backup copies of working tunes.

Timing Lights: Precision Ignition Control

Despite electronic ignition advances, timing lights remain essential for verifying and adjusting ignition timing. They’re particularly crucial when:

- Installing aftermarket distributors

- Changing cam timing

- Diagnosing ignition problems

- Setting initial timing after engine rebuilds

Modern timing lights offer features beyond basic functionality:

- Digital advance readouts showing exact timing degrees

- Adjustable advance for checking total timing

- Tachometer functions displaying engine RPM

- Dwell meters for older points-based ignitions

Using a timing light properly requires understanding your engine’s specifications. Most engines have timing marks on the harmonic balancer and a pointer on the timing cover. You’ll connect the timing light to your battery and number one spark plug wire (or coil trigger), then observe the marks while the engine runs.

Critical timing considerations:

- Too much advance causes detonation and potential engine damage

- Insufficient advance reduces power and efficiency

- Timing requirements change with modifications

- Higher octane fuel allows more aggressive timing

Quality timing lights range from $30 basic models to $200+ professional units with advanced features. Even basic models work well for most garage tuning needs.

Precision Measuring Devices: Where Accuracy Counts

In engine building and modification, measurements often need accuracy to thousandths of an inch. The right measuring tools ensure parts fit correctly, clearances meet specifications, and assemblies stay within tolerance.

Torque Wrenches: The Right Tightness Matters

A torque wrench might seem basic, but it’s absolutely critical for proper assembly. Over-tightening can strip threads, warp components, or cause immediate failure. Under-tightening leads to loosening, leaks, and potential catastrophic failure.

Three main types serve different purposes:

Click-Type Torque Wrenches are most popular for general use:

- Audible/tactile click at preset torque

- Good for most automotive applications

- Typically accurate to ±4%

- Range from 10-250 ft-lbs in various sizes

Beam-Type Torque Wrenches offer simplicity and reliability:

- No calibration required

- Visual torque indication

- Less convenient but very durable

- Ideal for checking other wrenches

Digital Torque Wrenches provide maximum precision:

- LCD displays showing exact torque

- Multiple unit conversions

- Angle measurements for torque-to-yield bolts

- Data logging capabilities

- Accuracy to ±1%

Critical applications requiring precise torque include:

- Head bolts/studs: Incorrect torque causes head gasket failure

- Connecting rod bolts: Over-torquing can cause rod failure

- Wheel lugs: Prevents wheels from loosening or warping rotors

- Suspension components: Ensures proper operation and safety

Invest in at least two torque wrenches covering different ranges. A 3/8″ drive (10-80 ft-lbs) handles most smaller fasteners, while a 1/2″ drive (30-250 ft-lbs) covers larger applications. Budget $50-$150 per wrench for quality tools that maintain accuracy.

Calipers and Micrometers: Measuring the Microscopic

When building performance engines or checking component wear, precision measuring instruments become indispensable. These tools measure dimensions that affect performance, reliability, and safety.

Calipers offer versatility for general measurements:

- Outside dimensions (piston diameter, shaft thickness)

- Inside dimensions (bore diameter, bearing clearance)

- Depth measurements (valve recession, step heights)

- Both metric and imperial units

Digital calipers speed up work with instant readings and zero-reset functions. Dial calipers provide reliability without batteries. Vernier calipers offer ultimate simplicity but require practice to read quickly.

Micrometers provide superior accuracy for critical measurements:

- Outside micrometers measure shaft diameters, brake rotor thickness

- Inside micrometers check cylinder bores, bearing housings

- Depth micrometers verify valve installed height, deck clearance

When selecting measuring tools, consider:

- Resolution: Most digital tools read to 0.0005″

- Accuracy: Quality instruments maintain ±0.001″ or better

- Range: Multiple sizes cover different measurement ranges

- Construction: Hardened stainless steel resists wear

- Certification: Some applications require traceable calibration

A basic measuring kit should include:

- 6″ digital or dial calipers ($30-$100)

- 0-1″ outside micrometer ($40-$100)

- Telescoping gauges for bore measurements ($30-$60)

- Feeler gauges for gap measurements ($10-$20)

Specialty Tools for Advanced Garage Tuners

As your skills advance, specialized tools become necessary for precise tuning and professional results. These instruments provide data and capabilities beyond basic tools.

Wideband Air/Fuel Ratio Meters: Fueling Perfection

A wideband oxygen sensor and controller is perhaps the most important tuning tool after basic diagnostics. Unlike narrow-band sensors that only indicate rich or lean, widebands provide exact air/fuel ratios across the entire operating range.

This precision matters because:

- Power production peaks at specific air/fuel ratios (typically 12.5-13.0:1 for naturally aspirated engines)

- Fuel economy improves with leaner mixtures (14.7:1 stoichiometric or leaner)

- Engine safety requires richer mixtures under boost (11.0-11.5:1 for turbocharged engines)

- Emissions compliance demands precise fuel control

Popular wideband systems include:

- Innovate Motorsports offers affordable, accurate solutions starting around $170

- AEM provides gauge-type displays with analog outputs for ECU integration

- PLX Devices combines wideband monitoring with multi-gauge displays

- Zeitronix includes advanced data logging capabilities

Installation typically involves:

- Welding a bung into the exhaust (before the catalytic converter)

- Installing the wideband sensor

- Mounting the controller/display

- Connecting power and ground

- Calibrating in free air

Critical wideband tips:

- Never use leaded fuel; it destroys sensors quickly

- Allow sensors to heat fully before trusting readings

- Replace sensors every 50,000 miles for consistent accuracy

- Use anti-seize on threads but keep it off sensor elements

Leak-Down Testers: Beyond Basic Compression

While compression testers show if cylinders hold pressure, leak-down testers reveal where pressure escapes. This additional information dramatically improves diagnostic accuracy.

Leak-down testing involves:

- Bringing each cylinder to TDC compression

- Applying regulated air pressure (typically 100 PSI)

- Measuring pressure loss percentage

- Listening for air escaping to identify leak locations

Interpreting results:

- Less than 5% leakage: Excellent seal

- 5-10% leakage: Acceptable for most engines

- 10-20% leakage: Marginal, may need attention

- Over 20% leakage: Repairs needed

Where escaping air indicates problems:

- Through intake: Intake valve not sealing

- Through exhaust: Exhaust valve issues

- Through oil filler: Ring or piston problems

- Bubbles in coolant: Head gasket or cracked head/block

Quality leak-down testers cost $70-$200 and require an air compressor capable of sustained 100+ PSI output.

Camshaft Degree Wheels: Perfect Valve Timing

When installing aftermarket camshafts or building race engines, degree wheels ensure precise valve timing. Even small timing errors significantly affect performance and potentially cause valve-to-piston contact.

The degreeing process verifies:

- Intake centerline matches cam card specifications

- Lobe separation angle is correct

- Advance or retard from indicated settings

- Total duration at specified lift points

Required tools include:

- Degree wheel (9-16″ diameter for accuracy)

- Pointer (rigid mount essential)

- Dial indicator with magnetic base

- Top dead center stop

- Calculator for averaging readings

While complex initially, degreeing cams prevents expensive mistakes and ensures optimal performance from aggressive profiles.

Building Your Tool Collection Strategically

Starting a garage tuning tool collection can feel overwhelming and expensive. Smart planning and prioritization help you build capabilities without breaking the bank.

Priority Levels for Tool Purchases

Must-Have First (Safety and Basics):

- Jack and jack stands

- Basic hand tools (sockets, wrenches, screwdrivers)

- Multimeter for electrical diagnosis

- OBD-II scanner for fault codes

- Torque wrench for proper assembly

- Safety equipment (glasses, gloves, fire extinguisher)

Important Additions (Improved Capability):

- Compression tester

- Vacuum gauge

- Timing light

- Digital calipers

- Wideband oxygen sensor

- Better diagnostic scanner with live data

Advanced Tools (Professional Results):

- Engine management tuning software

- Leak-down tester

- Micrometers

- Degree wheel

- Bore gauge

- Dyno time (rented)

Budget-Friendly Strategies

Buy quality where it matters most: Precision measuring tools, torque wrenches, and diagnostic equipment should be name-brand quality. Save money on less critical items like organizers, basic hand tools, and shop supplies.

Consider used tools carefully: Electronic diagnostic tools often become obsolete quickly, making used units risky. Mechanical measuring tools and hand tools can be excellent used purchases if you verify their condition and accuracy.

Group purchases and tool sharing: Partner with other enthusiasts to buy expensive specialty tools you’ll use infrequently. Sharing costs makes professional-grade equipment accessible.

Rent before buying: Test expensive tools through rental before committing to purchase. This helps you understand whether you’ll use them enough to justify ownership.

Maintaining and Calibrating Your Tools

Tools are investments that require proper care and regular calibration to maintain accuracy and longevity. Neglected tools provide false readings, leading to improper adjustments and potential damage.

Calibration Schedules

Torque wrenches: Check annually or after drops/impacts. Many tool stores offer free checking. Professional calibration costs $30-$50 but ensures accuracy for critical applications.

Digital instruments: Follow manufacturer recommendations, typically annual calibration. Some units self-calibrate; others require professional service.

Measuring tools: Check against known standards regularly. Gauge blocks or calibration standards verify accuracy.

Storage and Care Best Practices

Climate control: Store precision tools in controlled environments. Humidity causes corrosion; temperature swings affect calibration.

Protective cases: Use supplied cases or create custom storage. Padding prevents damage during transport and storage.

Regular cleaning: Remove dirt, oil, and debris after each use. Lubricate moving parts according to manufacturer specifications.

Documentation: Keep calibration certificates, manuals, and maintenance records. This preserves value and ensures proper use.

Common Mistakes to Avoid

Even experienced tuners make errors that compromise results or damage equipment. Learning from others’ mistakes saves time, money, and frustration.

Diagnostic Pitfalls

Ignoring basic checks: Don’t assume complex problems without checking basics first. Verify battery voltage, grounds, and connections before diving deep.

Trusting single readings: Take multiple measurements and cross-reference results. One anomalous reading might indicate tool problems rather than engine issues.

Skipping documentation: Record baseline measurements before modifications. Without before data, you can’t quantify improvements.

Tool Misuse

Exceeding tool limits: Using 1/4″ drive sockets on high-torque applications breaks tools and risks injury. Match tool capacity to job requirements.

Improvising with wrong tools: Using adjustable wrenches on fuel fittings rounds fittings and causes leaks. Invest in proper flare nut wrenches.

Neglecting safety equipment: Eye protection, gloves, and proper jack stands aren’t optional. Medical bills exceed tool costs exponentially.

The Future of Garage Tuning Tools

The automotive industry’s rapid evolution brings new technologies and tools to garage tuners. Staying current with developments helps you maintain relevant skills and capabilities.

Emerging Technologies

Wireless diagnostics: Bluetooth and WiFi-enabled tools eliminate cables and improve accessibility. Tablet-based interfaces provide superior displays and functionality.

Cloud-based tuning: Remote tuning services and cloud storage for calibrations enable collaboration and professional support regardless of location.

Electric vehicle tools: As EVs become mainstream, specialized tools for high-voltage systems, battery diagnostics, and motor controllers become necessary.

3D scanning and printing: Creating custom parts and reverse-engineering components becomes accessible to home enthusiasts.

Continuous Learning

Online resources: Forums, YouTube channels, and online courses provide free education. Manufacturer training materials offer deep technical knowledge.

Local communities: Car clubs, racing organizations, and technical schools offer hands-on learning opportunities and tool access.

Professional development: ASE certifications and manufacturer training programs validate skills and open career opportunities.

Conclusion: Investing in Your Passion

Building a comprehensive garage tuning tool collection requires significant investment of both money and time, but the rewards justify the effort. Quality tools transform frustrating struggles into enjoyable challenges, enable modifications impossible otherwise, and potentially save thousands in shop labor costs.

Remember that tools are enablers, not magic solutions. The best equipment can’t replace knowledge, experience, and patience. Start with basics, learn continuously, and gradually expand your capabilities as skills develop.

Whether you’re chasing quarter-mile times, carving canyon roads, or simply maintaining your daily driver, having the right tools makes every project more successful and satisfying. Each tool in your collection represents expanded capability and another step toward automotive mastery.

The journey from basic maintenance to advanced tuning is incredibly rewarding. With proper tools and dedication to learning, your garage becomes a laboratory where mechanical dreams become reality. Start building your collection today, and discover what’s possible when you have the right equipment for the job.

Additional Resources

- HP Academy – Professional online tuning courses covering engine management, wiring, and dyno operation

- Maximum Motorsports Technical Articles – Detailed technical guides for suspension setup and chassis tuning

- Engine Builder Magazine – Industry news and technical articles for serious engine builders