Table of Contents

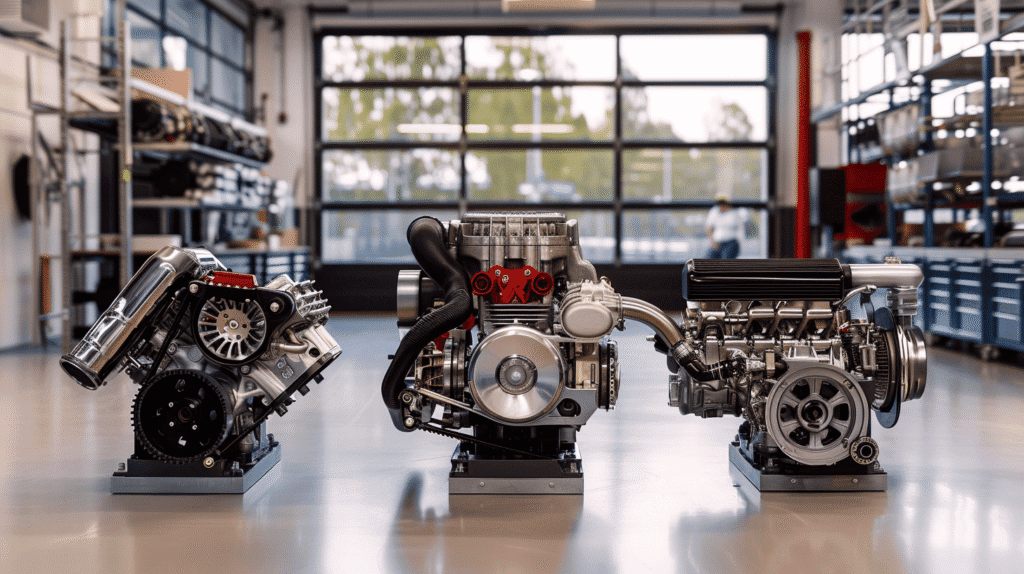

Naturally Aspirated vs Turbo vs Supercharger: Which Performance Build Is Best for Your Engine?

Introduction: The Fundamental Decision in Performance Building

The choice between keeping your engine naturally aspirated (N/A), adding a turbocharger, or bolting on a supercharger represents one of the most critical decisions in automotive performance building. This isn’t just about adding power—it’s about fundamentally changing your engine’s character, your driving experience, and your relationship with your vehicle.

Each approach to making power comes with its own philosophy. Naturally aspirated engines represent purity and simplicity, delivering power exactly as the engineers intended. Turbochargers embody efficiency and technology, extracting maximum power from exhaust energy that would otherwise be wasted. Superchargers prioritize immediate response and linear power delivery, trading some efficiency for instant gratification.

The implications of your choice extend far beyond peak horsepower numbers. Your decision affects everything from daily drivability and fuel economy to maintenance requirements and long-term reliability. It influences how your car sounds, how it responds to modifications, and even how it behaves in different weather conditions. Whether you’re building a weekend track weapon, a street performance machine, or simply want to understand the technology better, this comprehensive guide will help you make an informed decision based on real-world experience, engineering principles, and practical considerations.

Understanding the Fundamentals: How Each System Creates Power

The Physics of Making Power

Before diving into specific technologies, understanding the basic equation of power production is essential:

Power = (Torque × RPM) / 5252

But torque itself comes from combustion pressure acting on the piston surface area and crank throw. The more air and fuel you can burn efficiently, the more power you make. All three approaches—naturally aspirated, turbo, and supercharger—are simply different methods of getting air into the engine.

The volumetric efficiency (VE) of an engine describes how effectively it fills its cylinders with air. A typical naturally aspirated engine achieves 80-90% VE at peak torque. Forced induction can push this well over 100%, effectively making your engine behave like a larger displacement unit.

How Naturally Aspirated Engines Work: The Purist’s Choice

Naturally aspirated engines rely solely on atmospheric pressure (14.7 psi at sea level) to fill the cylinders during the intake stroke. As the piston moves down, it creates a vacuum that atmospheric pressure rushes to fill.

The Naturally Aspirated Breathing Process

- Intake stroke begins: Piston moves down, creating vacuum

- Atmospheric pressure: Pushes air through the intake

- Valve timing optimization: Variable valve timing maximizes flow

- Resonance tuning: Intake and exhaust tuning creates pressure waves

Advanced Naturally Aspirated Technologies

Modern naturally aspirated engines employ sophisticated technologies to maximize performance:

- Variable Valve Timing (VVT): Optimizes cam timing for different RPMs

- Variable Valve Lift: Changes how far valves open (VTEC, VANOS)

- Variable Intake Manifolds: Alter runner length for torque optimization

- High Compression Ratios: 11:1 to 14:1 common in modern performance engines

- Direct Injection: Enables higher compression without knock

Naturally Aspirated Power Characteristics

The power delivery of naturally aspirated engines is characterized by:

- Linear progression: Power builds predictably with RPM

- Instant response: No delay between throttle input and power

- High-RPM capability: Often rev higher than forced induction

- Atmospheric sensitivity: Power decreases with altitude

- Temperature stability: Less affected by heat soak

Turbocharging Essentials: Harnessing Exhaust Energy

Turbochargers represent one of the most elegant solutions in automotive engineering—using waste exhaust energy to compress intake air.

The Turbocharging Cycle

- Exhaust gases exit: Hot, high-pressure gases leave combustion chamber

- Turbine wheel spins: Exhaust energy rotates turbine at 100,000-250,000 RPM

- Compressor wheel driven: Connected shaft spins compressor

- Air compression: Intake air compressed to 5-30+ PSI

- Intercooling: Compressed air cooled before entering engine

- Increased density: Cooler, denser air allows more fuel

Turbocharger Components Explained

The Turbine Side

- Turbine housing: A/R ratio determines spool characteristics

- Turbine wheel: Extracts energy from exhaust

- Wastegate: Bypasses exhaust to control boost

- Materials: Inconel or ceramic for extreme heat resistance

The Compressor Side

- Compressor wheel: Aluminum or titanium for light weight

- Compressor housing: Shaped for optimal airflow

- Anti-surge porting: Prevents compressor stall

- Blow-off/bypass valve: Releases pressure during throttle lift

The Center Section

- Journal bearings: Traditional, oil-cooled

- Ball bearings: Faster spool, less friction

- Oil supply: Critical for cooling and lubrication

- Water cooling: Prevents oil coking after shutdown

Understanding Turbo Lag and Modern Solutions

Turbo lag—the delay between throttle application and boost delivery—has been the traditional drawback of turbocharging. Modern technology has largely addressed this:

Traditional Lag Causes

- Turbine inertia: Time needed to accelerate heavy wheels

- Exhaust volume: Building sufficient exhaust flow

- Boost threshold: Minimum RPM for boost production

Modern Lag Reduction Technologies

- Twin-scroll turbos: Separate exhaust pulses for better spool

- Variable geometry turbos: Adjust turbine housing for optimal flow

- Electric turbos: Motor-assisted spool-up

- Twin-turbo setups: Small turbo for low-end, large for top-end

- Anti-lag systems: Keep turbo spooled between shifts

Supercharger Fundamentals: Instant Forced Induction

Superchargers take a more direct approach to forced induction, using engine power to mechanically drive a compressor.

Types of Superchargers

Roots-Type Superchargers

The classic American muscle car supercharger:

- Design: Two or three-lobe rotors mesh to move air

- Characteristics: Instant boost, great low-end torque

- Efficiency: 50-60% peak, generates significant heat

- Sound: Distinctive whine, especially under load

- Applications: Drag racing, street performance

Twin-Screw Superchargers

Evolution of the Roots design:

- Design: Helical rotors compress air internally

- Characteristics: More efficient than Roots, still instant

- Efficiency: 65-75% peak

- Heat generation: Less than Roots but still significant

- Cost: More expensive than Roots types

Centrifugal Superchargers

Basically a belt-driven turbocharger compressor:

- Design: Similar to turbo compressor wheel

- Characteristics: Boost increases with RPM

- Efficiency: 70-80% peak, most efficient type

- Power curve: More like a turbo, less low-end

- Installation: Often easier, more compact

Supercharger Drive Systems

Belt Drive Considerations

- Cog belt: Most common, reliable, some slip at high boost

- Gear drive: No slip, louder, more expensive

- Clutched: Engages only when needed, complex

- Ratio selection: Determines boost curve and peak

Parasitic Loss Reality

Superchargers consume engine power to make power:

- Typical loss: 50-100 HP to drive at peak boost

- Efficiency factor: Must make more than consumed

- Low-RPM impact: Less noticeable at lower speeds

- Heat generation: Parasitic loss becomes heat

Comprehensive Performance Comparison

Power Output Analysis: Real Numbers and Expectations

Understanding realistic power gains helps set appropriate expectations and budget accordingly.

Naturally Aspirated Power Potential

Mild Naturally Aspirated Builds (Stock Internals)

- Intake/exhaust/tune: 10-15% gain (20-30 HP on 200 HP engine)

- Cams and heads: 20-30% gain possible

- Compression increase: 5-10% per point

- Individual throttle bodies: 15-20% at high RPM

- Total realistic gain: 30-40% with full bolt-ons

Wild Naturally Aspirated Builds (Built Internals)

- High compression (13:1+): Significant gains, requires race fuel

- Aggressive cams: Sacrifice low-end for top-end

- Extensive head work: Port, polish, larger valves

- Stroker kits: Increase displacement

- Total potential: 50-100% over stock (becomes peaky)

Turbocharged Power Potential

Conservative Turbo Builds (5-10 PSI)

- Stock internals safe: Most engines handle this

- Power gain: 40-60% over naturally aspirated

- Daily drivable: Maintains good street manners

- Fuel requirements: 91-93 octane usually sufficient

- Reliability: Near-stock with proper tuning

Aggressive Turbo Builds (15-30+ PSI)

- Built internals required: Forged pistons, rods minimum

- Power gain: 100-300% possible

- Lag becomes factor: Large turbos = more lag

- Supporting mods: Fuel system, cooling, transmission

- Race fuel/E85: Often required for safety

Supercharged Power Potential

Mild Supercharger Builds (5-8 PSI)

- Stock internals typically safe: Check compression ratio

- Power gain: 35-50% typical

- Instant response maintained: No lag introduction

- Heat management: Intercooling recommended

- Daily driver friendly: Very streetable

High-Boost Supercharger Builds (12-20+ PSI)

- Internals needed: Similar to turbo requirements

- Power gain: 80-150% possible

- Heat becomes critical: Extensive cooling required

- Belt slip concerns: May need cog or gear drive

- Efficiency drops: Parasitic losses increase

Torque Delivery Characteristics

The way each system delivers torque fundamentally changes the driving experience.

Naturally Aspirated Torque Curves

- Peak location: Usually 75-85% of redline

- Curve shape: Gradual rise and fall

- Consistency: Very repeatable

- Modification effects: Cams shift peak RPM

Turbocharged Torque Curves

- Peak location: Mid-range, broad plateau possible

- Curve shape: Rapid rise after spool, may taper at high RPM

- Boost by gear: Can vary torque for traction

- Size effects: Larger turbos shift torque higher

Supercharged Torque Curves

- Peak location: Often lower than naturally aspirated

- Curve shape: Immediate rise, gradual increase

- Consistency: Very predictable

- Type differences: Roots = flat, Centrifugal = rising

Real-World Drivability Comparison

Daily Driving Characteristics

Naturally Aspirated Daily Driving

Pros:

- Predictable power delivery

- Excellent part-throttle response

- No heat soak issues

- Best fuel economy at cruise

- Minimal maintenance concerns

Cons:

- Less passing power

- Altitude affects performance

- Limited tuning potential

- May feel slow by modern standards

Turbocharged Daily Driving

Pros:

- Excellent fuel economy when out of boost

- Strong midrange for passing

- Altitude compensation automatic

- Modern turbos have minimal lag

- Exciting power delivery

Cons:

- Heat soak in traffic

- Potential for boost creep

- More complex troubleshooting

- Premium fuel typically required

- Oil change intervals critical

Supercharged Daily Driving

Pros:

- Instant throttle response

- Linear power delivery

- No lag in any situation

- Consistent performance

- Great sound characteristics

Cons:

- Lower fuel economy overall

- Heat soak issues

- Belt wear and tension

- Hood clearance challenges

- Premium fuel required

Engine Compatibility and Required Modifications

Assessing Your Engine’s Forced Induction Potential

Not all engines are created equal when it comes to handling boost. Understanding your engine’s limitations prevents expensive failures.

Compression Ratio Considerations

Starting Compression Guidelines

- 11.0:1 and higher: Limited boost potential (5-7 PSI max on pump gas)

- 10.0-11.0:1: Moderate boost friendly (8-10 PSI)

- 9.0-10.0:1: Good boost platform (10-15 PSI)

- 8.0-9.0:1: Built for boost (15+ PSI)

Compression Reduction Options

- Thicker head gasket: Simple, 0.5-1.0 point reduction

- Dished pistons: Expensive but effective

- Combustion chamber work: Removes material

- Stroker with same bore: Increases swept volume

Internal Component Strength Requirements

Stock Internal Limits (General Guidelines)

- Cast pistons: 400-450 HP typically maximum

- Powdered metal rods: 500-550 HP limit

- Cast crankshaft: 600-700 HP boundary

- Stock head gaskets: Boost-dependent, usually 15 PSI max

- Stock head bolts: Often first failure point

Forged Internal Benefits

- Forged pistons: Handle 2-3x stock power

- Forged rods: H-beam or I-beam, application specific

- Forged crankshaft: Rarely the limiting factor

- ARP studs: Essential for high boost

- MLS gaskets: Better sealing under boost

Supporting Modifications by Build Type

Fuel System Requirements

Naturally Aspirated Fuel Needs

- Injector sizing: 80% duty cycle at peak power

- Fuel pump: Stock often adequate

- Fuel pressure: Stock regulator usually fine

- Lines and rails: Stock typically sufficient

- Return style: Not usually necessary

Forced Induction Fuel Demands

- Injector sizing: Plan for 30% more than calculated

- Fuel pump requirements: 255 LPH minimum for mild boost

- Dual pumps: Often needed over 500 HP

- Return-style system: Maintains consistent pressure

- Flex fuel sensor: If running E85

Cooling System Upgrades

Naturally Aspirated Cooling Needs

- Radiator: Stock usually adequate

- Oil cooler: Beneficial for track use

- Thermostat: Lower temp for performance

- Fan upgrades: Higher CFM for heat extraction

- Coolant: Quality more important than capacity

Turbo Cooling Requirements

- Intercooler: Air-to-air or air-to-water

- Radiator upgrade: 30-40% more capacity needed

- Oil cooler: Essential for bearing life

- Turbo timer: Prevents oil coking

- Heat shielding: Protects components

- Hood venting: Helps extract engine bay heat

Supercharger Cooling Demands

- Intercooler: Critical for Roots/twin-screw

- Heat exchanger: For air-to-water setups

- Radiator upgrade: Similar to turbo needs

- Belt cooling: Some setups benefit

- Methanol injection: Supplemental cooling option

Engine Management and Tuning Requirements

Naturally Aspirated Tuning

Naturally Aspirated Tuning Parameters

- Ignition timing: Optimize for fuel grade

- Cam timing: If variable, adjust for goals

- Fuel trim: Dial in AFR targets

- Rev limit: Can often raise safely

- VTEC point: Optimize crossover (Honda)

Naturally Aspirated Tuning Tools

- Reflash: Stock ECU modification

- Piggyback: Interceptor modules

- Standalone: Full control, rarely needed

Forced Induction Tuning Complexity

Critical Boost Parameters

- Boost control: Target vs actual boost

- Ignition retard: Reduce timing under boost

- Fuel enrichment: Richer AFR for safety

- Boost by gear: Traction management

- Safety limits: Overboost protection

Advanced Tuning Features

- Flex fuel: Auto-adjust for ethanol content

- Traction control: Boost-based intervention

- Launch control: Boost building strategies

- No-lift shift: Maintains boost between gears

- Anti-lag: Keeps turbo spooled

Cost Analysis: Real Budget Considerations

Initial Purchase and Installation Costs

Naturally Aspirated Build Costs

Basic Naturally Aspirated Build ($2,000-5,000)

- Headers: $400-800

- Full exhaust: $500-1,200

- Cold air intake: $200-400

- ECU tune: $400-700

- Mild cams: $400-600

- Installation: $500-1,500

Serious Naturally Aspirated Build ($5,000-15,000)

- Ported heads: $1,500-3,000

- Aggressive cams: $600-1,200

- Valve springs/retainers: $400-800

- Individual throttle bodies: $2,000-4,000

- Standalone ECU: $1,500-3,000

- Professional assembly: $2,000-5,000

Turbo Build Costs

Entry-Level Turbo Kit ($3,000-6,000)

- Basic kit: $2,000-3,500

- Installation: $1,000-2,000

- Tuning: $500-1,000

- Gauges: $200-400

- BOV/Wastegate: Included or $300-500

Quality Turbo Build ($6,000-15,000)

- Name-brand kit: $4,000-7,000

- Fuel system: $1,000-2,000

- Engine management: $1,500-2,500

- Cooling upgrades: $1,000-2,000

- Installation/tuning: $2,000-3,500

- Clutch upgrade: $800-1,500

Built Motor Turbo ($15,000-30,000+)

- Forged internals: $3,000-5,000

- Machine work: $1,500-2,500

- Big turbo kit: $5,000-10,000

- Supporting mods: $3,000-5,000

- Transmission build: $2,000-4,000

- Professional build: $3,000-6,000

Supercharger Build Costs

Roots/Twin-Screw Kit ($4,000-8,000)

- Complete kit: $3,000-5,500

- Installation: $800-1,500

- Tuning: $500-1,000

- Heat management: $500-1,000

- Pulley upgrades: $200-400

Centrifugal Kit ($3,500-6,500)

- Complete kit: $2,500-4,500

- Installation: $600-1,200

- Tuning: $500-1,000

- BOV/Bypass: Usually included

- Gauge package: $200-400

Long-Term Ownership Costs

Maintenance Cost Comparison

Naturally Aspirated Maintenance (Annual)

- Oil changes: $200-400 (synthetic)

- Spark plugs: $50-150

- Air filter: $50-100

- Valve adjustments: $0-300

- Total: $300-950

Turbo Maintenance (Annual)

- Oil changes: $400-600 (more frequent)

- Spark plugs: $100-200 (more frequent)

- Turbo inspection: $100-200

- Coolant service: $100-150

- Boost leak testing: $50-100

- Total: $750-1,250

Supercharger Maintenance (Annual)

- Oil changes: $300-500

- Belt replacement: $100-200

- Supercharger oil: $50-100

- Tensioner service: $100-200

- Coupler inspection: $50-100

- Total: $600-1,100

Failure Mode Costs

Common Naturally Aspirated Failures

- Valve train wear: $500-2,000

- Timing chain/belt: $800-1,500

- Head gasket: $1,500-3,000

Common Turbo Failures

- Turbo rebuild: $500-1,500

- Blown motor: $5,000-15,000

- Intercooler damage: $300-800

- Wastegate failure: $200-500

Common Supercharger Failures

- Bearing failure: $800-2,000

- Belt shredding damage: $500-2,000

- Snout seal leak: $300-600

- Bypass valve: $200-400

Application-Specific Recommendations

Best Builds by Vehicle Type

Sport Compact Cars (Civic, GTI, WRX, Miata)

Recommended Approach

Best Overall: Turbocharger

- Takes advantage of small displacement

- Huge aftermarket support

- Best power-per-dollar

- Can maintain daily drivability

Alternative: Supercharger (Miata/86)

- Better for autocross/track

- Linear power delivery

- Simpler installation

- Less heat soak issues

Avoid Unless Specific Goals

Naturally Aspirated builds on small engines rarely worth it unless:

- Class racing requirements

- Maximum reliability needed

- Budget extremely limited

American V8s (Mustang, Camaro, Corvette)

Recommended Approach

Tie: Supercharger or Naturally Aspirated

Supercharger Benefits:

- Massive torque everywhere

- Traditional muscle car feel

- Easier packaging than turbos

- Great sound

Naturally Aspirated Benefits:

- Simplicity and reliability

- High-revving capability

- Lower weight

- Classic approach

Turbo Considerations:

- Maximum power potential

- Packaging challenges

- Heat management critical

- Less traditional feel

European Performance (BMW, Audi, Mercedes)

Recommended Approach

Best: Embrace Factory Forced Induction

- Already engineered for boost

- Upgrade existing turbo

- Tune for more power

- Maintain OEM reliability

For Naturally Aspirated Models: Supercharger

- Several quality kits available

- Maintains European refinement

- Good warranty options

- Professional installation network

Japanese Luxury/GT (350Z, G35, Supra, RX-7)

Recommended Approach

Depends on Platform:

Turbo Platforms (Supra, RX-7):

- Upgrade factory setup

- Single turbo conversions popular

- Huge power potential

Naturally Aspirated Platforms (350Z, G35):

- Turbo for maximum power

- Supercharger for street driving

- Naturally aspirated builds limited potential

Driving Style Considerations

Track and Road Course

Best Choice: Naturally Aspirated or Centrifugal Supercharger

Why Naturally Aspirated Works:

- Consistent lap times

- No heat soak issues

- Predictable behavior

- Lighter weight

Why Centrifugal Works:

- Progressive power delivery

- Better heat management than Roots

- Maintains naturally aspirated feel with more power

Challenges with Turbo:

- Heat management critical

- Boost control complexity

- Potential for inconsistency

Drag Racing

Best Choice: Turbocharged

Why Turbo Dominates:

- Maximum power potential

- Boost by gear for traction

- Anti-lag keeps boost up

- Weight distribution benefits

Supercharger Alternative:

- Instant power off line

- Simpler to tune

- Very consistent

- Traditional approach

Street Performance

Best Choice: Supercharger (Roots/Twin-Screw)

Why Supercharger Excels:

- Instant response in traffic

- Linear, predictable power

- Great sound

- Reliable power delivery

Turbo Alternative:

- Modern small turbos work well

- Better fuel economy

- More tuning flexibility

- Sleeper potential

Daily Driver Only

Best Choice: Mild Turbo or Stay Naturally Aspirated

Why Conservative Approach:

- Maintains reliability

- Keeps warranty (if applicable)

- Reasonable fuel economy

- Lower maintenance costs

Future-Proofing Your Build

Emerging Technologies

Electric-Assisted Turbocharging

- 48V systems: Enable electric turbos

- Instant spool: Eliminates lag entirely

- Regeneration: Harvests exhaust energy

- OEM adoption: Mercedes, Audi leading

Variable Compression Engines

- Infiniti VC-T: Production variable compression

- Boost optimization: Adjust for conditions

- Efficiency gains: Best of both worlds

- Future applications: Spreading to more manufacturers

Advanced Materials

- 3D-printed turbos: Complex geometries possible

- Carbon fiber wheels: Reduced rotating mass

- Ceramic bearings: Higher temperature capability

- Titanium aluminide: Lighter turbine wheels

Regulatory Considerations

Emissions Compliance

- CARB approval: Critical in California

- EPA regulations: Federal requirements

- State inspections: Vary significantly

- Future restrictions: Likely to tighten

Insurance and Legal Issues

- Disclosure requirements: Must inform insurer

- Premium impacts: Forced induction increases

- Street legality: Varies by location

- Track insurance: Usually separate policy

Resale Value Impact

Value Retention Factors

- Quality of installation: Professional vs amateur

- Documentation: Receipts and dyno sheets

- Reversibility: Ability to return to stock

- Brand reputation: Known quality parts

- Maintenance records: Proof of care

Making Your Final Decision: A Strategic Framework

The Decision Matrix

Priority Assessment

Rate each factor 1-10 for importance to you:

- Maximum power potential

- Daily drivability

- Reliability/simplicity

- Initial cost

- Operating costs

- Throttle response

- Sound character

- Modification potential

- Resale value

- Uniqueness factor

Scoring by System

If Priorities 3, 6, 7 Score Highest: Go Naturally Aspirated

- You value simplicity

- Response matters most

- Traditional approach appeals

If Priorities 1, 8, 10 Score Highest: Go Turbo

- Maximum power is goal

- Enjoy tuning and modifications

- Want cutting-edge performance

If Priorities 2, 6, 7 Score Highest: Go Supercharger

- Want forced induction benefits

- Need instant response

- Appreciate mechanical whine

Common Mistakes to Avoid

Universal Mistakes

- Cheaping out on tuning: Most critical component

- Ignoring supporting mods: Recipe for failure

- Rushing the build: Take time, do it right

- Following internet advice blindly: Every build unique

- Skipping break-in procedures: Critical for longevity

Naturally Aspirated Specific Mistakes

- Expecting huge gains: Reality check needed

- Wrong cam selection: Ruins street manners

- Ignoring compression limits: Detonation kills

- Mismatched components: Must work together

Turbo Specific Mistakes

- Sizing too large: Lag ruins experience

- Weak tune safety: Lean = blown engine

- Cheap intercoolers: Heat soak kills power

- Ignoring oil requirements: Turbos need flow

Supercharger Mistakes

- Undersized cooling: Heat kills everything

- Wrong pulley size: Over-spinning damages

- Cheap belts: Slip or break frequently

- Ignoring parasitic loss: Affects entire calculation

Conclusion: Your Path to Power

The choice between naturally aspirated, turbocharged, or supercharged ultimately comes down to your specific goals, budget, and preferences. There’s no universally “best” choice—only the best choice for your specific situation.

Choose naturally aspirated if you value simplicity, reliability, and pure driving connection. The linear power delivery and mechanical simplicity of naturally aspirated builds offer an engaging driving experience without the complexity of forced induction. While power gains are limited compared to boost, the reliability and lower maintenance requirements make naturally aspirated builds perfect for dedicated track cars or those who prioritize the driving experience over peak power.

Choose turbocharged if you want maximum power potential and efficiency. Modern turbo technology has largely eliminated traditional drawbacks like lag, while maintaining the ability to produce enormous power from small displacements. The complexity is worth it for those chasing big power numbers or those who enjoy the tuning and optimization process. Turbos remain the technology of choice for setting records and pushing boundaries.

Choose supercharged if instant throttle response and linear power delivery are priorities. The mechanical connection between engine and supercharger ensures power is always available exactly when you need it. While efficiency isn’t their strong suit, superchargers offer the best of both worlds—forced induction power levels with naturally aspirated throttle response. They’re ideal for street performance where immediate power delivery matters more than peak numbers.

Remember that your first build doesn’t have to be your last. Many enthusiasts start with basic naturally aspirated modifications to learn their platform, then progress to forced induction as skills and budgets allow. The journey is often as rewarding as the destination.

Whatever path you choose, invest in quality components, professional tuning, and proper supporting modifications. A well-executed mild build will always outperform and outlast a poorly planned aggressive setup. Take time to research your specific platform, connect with other owners who’ve done similar builds, and always budget for more than just the headline components.

The road to power is paved with informed decisions, quality components, and careful execution. Whether you’re chasing lap times, quarter-mile records, or simply want to put a bigger smile on your face during the daily commute, understanding the fundamental differences between naturally aspirated, turbo, and supercharged builds ensures you’ll make the right choice for your goals.

Drive fast, build smart, and enjoy the journey.