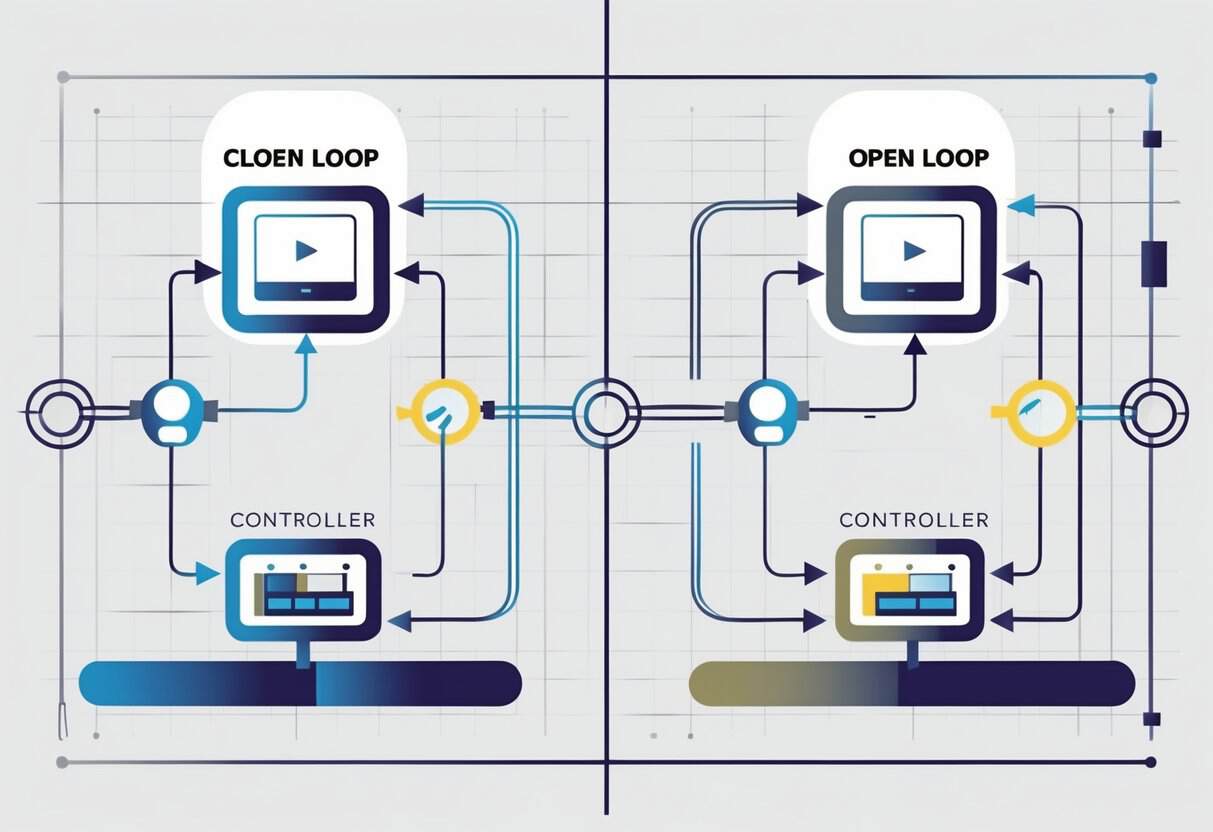

When you’re dealing with open loop and closed loop systems, you’re basically picking how a process keeps itself in check. Open loop systems just follow preset instructions—no feedback, no second guessing. Closed loop systems, on the other hand, use feedback to adjust and (hopefully) improve their operation. Knowing the difference can save you some headaches down the road.

Open loop systems are usually simpler. They skip the step where you check if things are actually working as planned.

Closed loop systems are always watching, monitoring results and tweaking things automatically to keep performance on track. This feedback loop lets them handle surprises better, which is why you see them in so many automated setups.

Key Takeways

- Open loop systems run without checking results.

- Closed loop systems adjust automatically using feedback.

- Choosing the right system depends on your control needs.

Fundamentals of Open Loop Operation

Open-loop systems do their thing without using feedback. You send a control action and hope for the best—there’s no measuring or adjusting based on what actually happens.

This approach relies on preset commands. It just assumes the process will work as intended.

How Open-Loop Systems Work

In an open-loop control system, you give an input or command and the system acts. There’s no checking to see if the output matches your goal.

Picture a toaster: it heats for a set time, whether the bread is already burnt or still pale.

This is why it’s called a non-feedback system. The output doesn’t loop back to influence anything. You just get input, then output, and that’s it.

Characteristics and Performance

Open-loop systems are straightforward. No need for sensors or extra gadgets to monitor output.

That usually means they’re cheaper and need less maintenance.

But since there’s no feedback, these systems can’t fix their own mistakes or react to unexpected changes. Performance is only as good as your initial setup and how steady your environment stays.

If something shifts, you might not get the results you wanted.

Advantages and Limitations

The big upside here is simplicity. You can set up open-loop systems fast, and they don’t have a ton of parts.

But you trade away flexibility. No feedback means you can’t fix errors or adapt to surprises. If the system’s off, it’ll just keep doing the wrong thing.

You’re putting a lot of trust in your original design.

Fundamentals of Closed Loop Operation

Closed-loop systems are a bit more involved. They’re always checking their output and making adjustments based on feedback.

Feedback signals are what guide the system in correcting mistakes. If you want to really understand closed-loop control, you’ve got to get familiar with these signals and how the controller responds.

Principles of Closed-Loop Systems

A closed-loop system keeps an eye on itself, comparing what it’s doing to what you actually want. You start with a goal or setpoint.

The system measures the real output, then decides if it needs to change anything.

This isn’t just a one-time thing—it happens over and over, all the time. The system keeps feeding its results back to the controller, forming a loop.

That’s where the “closed-loop” name comes from.

You count on this loop to keep things stable and accurate. The idea is to shrink the gap between what you want and what you get.

Role of Feedback and Feedback Signals

Feedback signals are like status reports from the output back to the controller. They tell you what’s going on right now.

You use this info to decide what to do next.

In closed-loop control, feedback is everything. It’s how the system corrects itself if things start to drift.

Usually, this is negative feedback—it works to reduce the difference between what you want and what you’re actually getting.

Without feedback, the controller is basically flying blind. Things could go wrong and you’d never know until it’s too late.

Feedback is your reality check.

Advantages and Challenges

Closed-loop control offers better accuracy. It keeps adjusting based on what’s really happening.

Your system can handle surprises and changes because it’s always self-correcting.

But there’s a trade-off. Closed-loop setups are more complicated and sometimes slower than open-loop ones.

You need sensors and extra components to measure feedback, which bumps up the cost and adds more stuff that could break.

And if the feedback isn’t set up right, you could end up with instability or wild over-corrections. That’s a headache nobody wants.

Error Signals and System Response

An error signal is just the difference between what you want (the setpoint) and what you’re actually getting (the output).

The controller looks at this error and decides how much to adjust.

Big error? Big correction. Small error? Just a little tweak.

How the controller responds to errors matters a lot. If it reacts too quickly, you might overshoot your target. Go too slow, and you’re always lagging behind.

It’s a balancing act—keeping the system quick but not jumpy.

Comparing Open Loop and Closed Loop Operations

There are some clear differences in how these systems deal with accuracy, efficiency, and making adjustments.

Accuracy and Stability

Closed loop systems use feedback to keep their output on target. They can fix mistakes and stay steady, even if things change.

You get better accuracy because the system is always watching and reacting.

Open loop systems don’t have that safety net. Their output is only as good as your initial input, so anything unexpected can throw things off.

If you need tight control, closed loop is the way to go. Open loop just can’t keep up if things start to shift.

Efficiency and Cost-Effectiveness

Open loop systems are often faster since they don’t wait around for feedback.

They’re simpler and usually cost less to build and run. If you don’t need pinpoint accuracy, you’ll save money by skipping all the extra hardware.

Closed loop systems need sensors and real-time adjustments, so they’re more complex and pricier. But you get better performance and less waste.

If you’re okay with “good enough,” open loop might be fine. If you want consistency and fewer do-overs, closed loop pays off in the long run.

Calibration and Gain

Tuning is a big deal for closed loop systems. You’ve got to set the gain just right—too high and things get unstable, too low and it’s sluggish.

Open loop calibration is simpler. Once you set it up, that’s it. But you can’t adapt if things change, so performance can slip over time.

Closed loop systems, when tuned right, stay sharp. Open loop relies on getting it right the first time, and hoping nothing drifts.

Applications and Use Cases

You’ll see open and closed loop systems used in different ways, depending on how much control and feedback the job needs.

Some tasks are fine with simple, no-feedback setups. Others really need that constant adjustment.

Automation and Industrial Control

In automation, closed loop systems are everywhere. They adjust on the fly, fixing mistakes as they happen.

If you’re running a manufacturing line, a closed loop setup can catch errors and keep quality up.

Open loop works when the task is repetitive and feedback isn’t a big deal. They’re easier and cheaper, so you might use them for things like basic conveyor belts or processes where nothing much changes.

When you’re choosing, think about whether your system needs to adapt or if “set it and forget it” is enough.

Sensor and Transducer Roles

Sensors and transducers are the backbone of closed loop control. They measure stuff like temperature, pressure, or position and feed that info to the controller.

If your system needs to react to changes, closed loop lets you do that quickly and accurately. Without sensors, open loop systems are just guessing.

Picking the right sensor makes a big difference. A good one keeps your system reliable and your controls sharp.

Torque and RPM Control

Closed loop control is crucial when you want spot-on torque or RPM tweaks in motors. It lets you check motor speed or force as it happens and make quick adjustments.

Say you’re working with robotics or CNC machines—closed loop really shines here. It keeps torque and speed steady, even if the load suddenly shifts.

Open loop control, on the other hand, is fine for basic motor jobs where you don’t care much about perfect speed or torque. It’s simpler, but if the load changes, you might run into trouble.