The 3.8L V6 engine was used across multiple Jeep models from 2002 until 2012 in both the Jeep Liberty and Jeep Wrangler. Unfortunately, this Pushrod V6 has developed an infamous reputation for experiencing a range of problems as miles add up. Learn about jeep 3.8 engine problems now!

In this detailed guide, we’ll uncover why Jeep’s 3.8L powerplant often suffers from issues like oil consumption, overheating, knocking noises, and even complete engine failure. Read on to learn the root causes, symptoms, and best ways to diagnose and repair common Jeep 3.8L engine problems.

FIND OUT ABOUT THE DIFFERENCE BETWEEN JL AND JK!

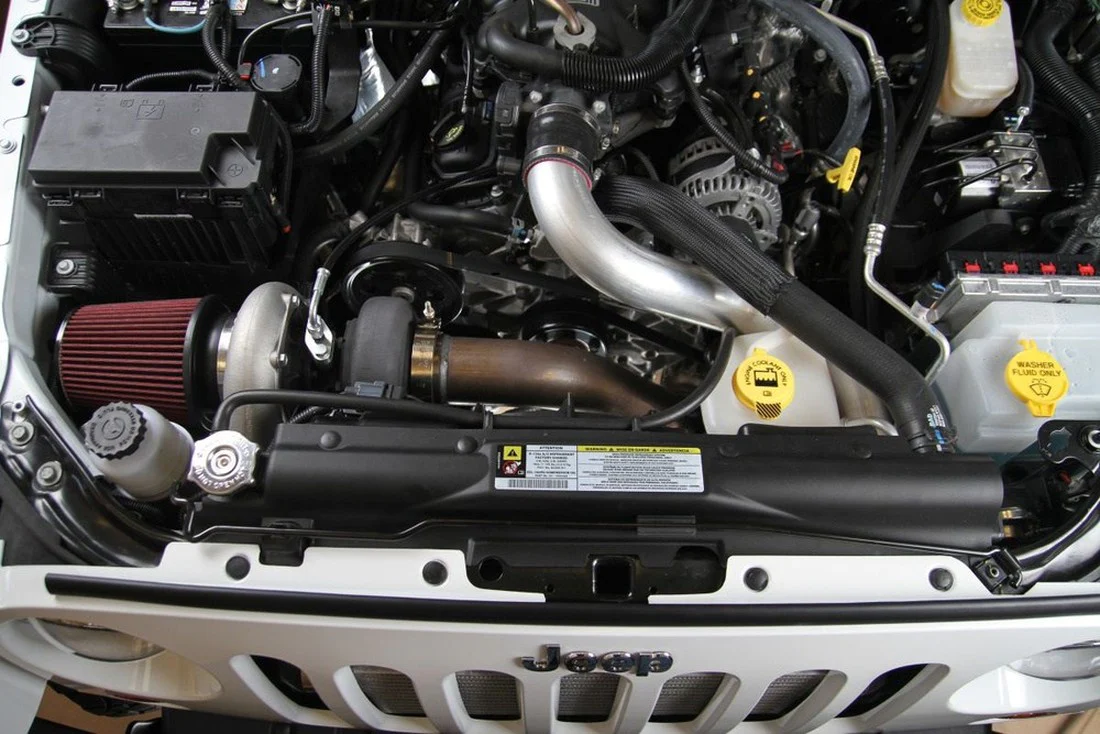

https://nashvilleperformance.com/jeep-wrangler-horsepower-upgrades-jeep-jk-performance-upgrades/

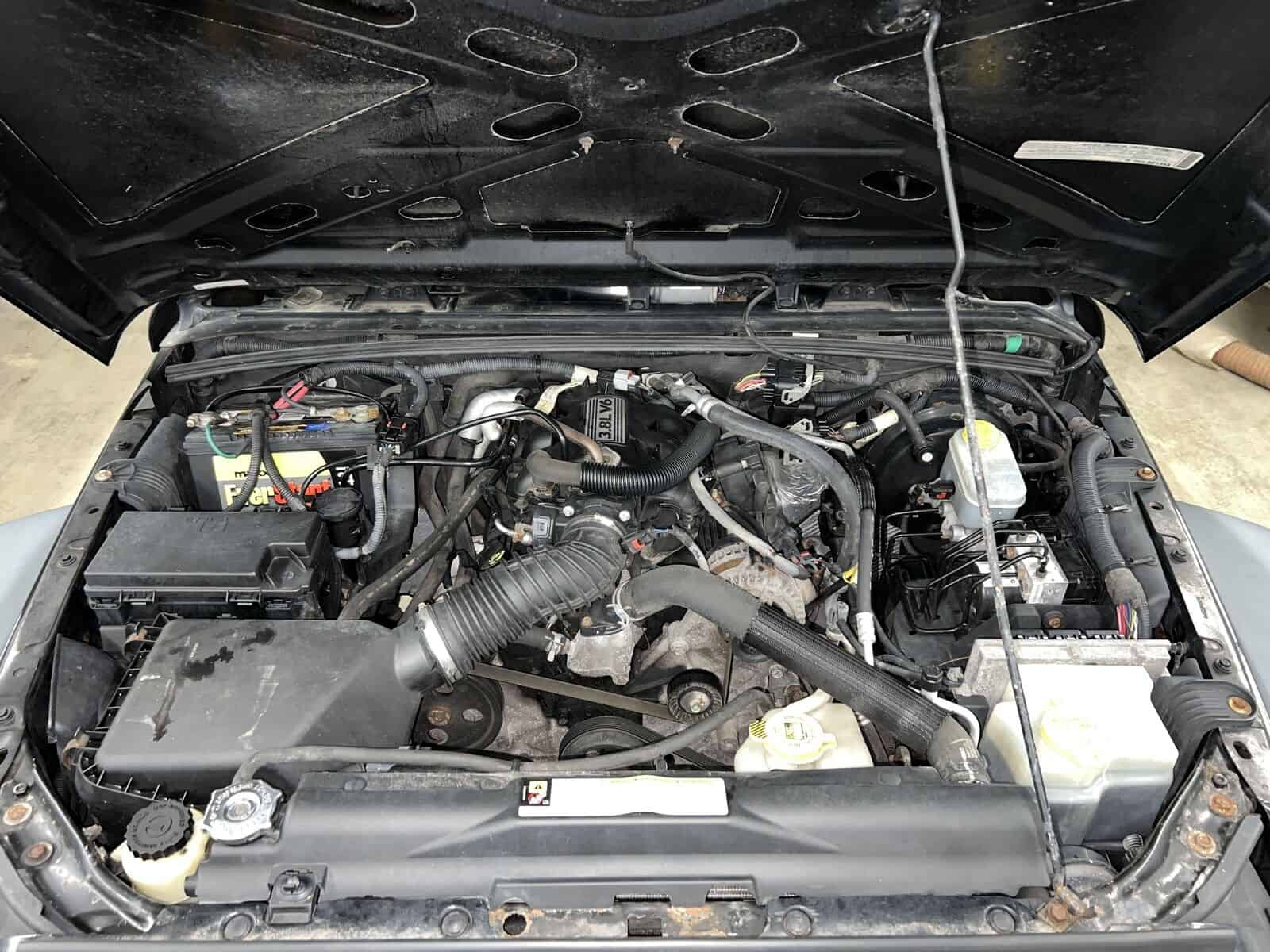

Overview of the 3.8L V6 Specs and Applications

First, a quick rundown of Jeep’s 3.8L V6 engine:

- Produces 202 to 210 horsepower depending on model year

- Makes between 235 and 245 lb-ft of torque

- All aluminum block and heads construction

- Pushrod overhead valve (OHV) design with hydraulic lifters

- Spark plugs are accessible from above unlike older V6 Jeeps

- Used in 2002-2012 Jeep Liberty and 2007-2011 Jeep Wrangler

Compared to other six-cylinder options like the 4.0 straight-6 or modern 3.6L V6, the 3.8L suffers more issues as the engine ages and mileage increases.

Knocking Noises and Engine Damage

One of the most worrisome Jeep 3.8L engine noises is persistent knocking or ticking coming from under the hood. This is often accompanied by a loss of power or sluggish acceleration.

What causes 3.8L knocking noises?

- Excessive main bearing clearance allowing the crank to rattle against the block

- Piston slap on the cylinder walls due to excessive piston-to-wall clearance

- Small end rod bearing failure resulting in rod knock

- Cam phaser or valvetrain issues causing timing chain rattle

Knocking or rattling noises signal internal engine damage. Driving with engine knocking can quickly lead to complete engine failure as bearings deteriorate or pistons seize.

Effects of the 3.8L knocking:

- Metal debris shed into the oil, contaminating the oiling system

- Compression loss as bearings wear down or pistons scuff

- Oil starvation and accelerated wear on valvetrain components

- Potential for the timing chain to jump time

If you hear pronounced and constant knocking from the Jeep’s 3.8L engine, have it inspected right away to determine the cause and prevent irreparable damage.

Oil Consumption and Sludge Buildup

Many Jeep Liberty and Wrangler owners find themselves having to top off the 3.8L V6 with extra quarts of oil between changes. This oil consumption happens as internal components like piston rings and valve guides wear over time.

Oil then makes its way past the rings into the combustion chamber to be burned off, or leaks past valves down into the cylinders.

What causes 3.8L oil consumption?

- Worn or broken piston rings failing to seal against cylinder walls

- Excessive cylinder wall and ring groove wear in high-mileage engines

- Stuck or broken piston ring lands preventing ring rotation

- Excess valve guide and stem seal wear allowing oil into cylinders or exhaust

Driving low on oil accelerates engine wear and can lead to overheating or even engine seizure. The other issue is thick oil sludge building up inside the engine:

Sludge buildup problems

- Clogs oil passages and restricts oil flow

- Oil pump gears wear quickly in sludged engines

- Reduced oil pressure and lack of lubrication

- Sludge debris can block oil galleys completely

If your 3.8L has started burning more than a quart of oil every 1,000-1,500 miles, seek a diagnosis for the root cause. Addressing worn parts like pistons and valve guides reduces oil loss while also preventing damaging sludge.

https://nashvilleperformance.com/best-winch-for-jeep-an-in-depth-review/

Overheating Issues and Coolant Leaks

It’s essential that engines maintain normal operating temperatures to avoid overheating damage. But Jeep’s 3.8L has its share of cooling system flaws:

What causes 3.8L engines to overheat?

- Compromised head gaskets leading to external coolant leaks or internal combustion gas leakage

- Broken plastic coolant fittings and boxes cracking over time

- Improper coolant mixture and old coolant losing effectiveness

- Thermostat failure in the closed position restricting coolant flow

- Cooling fan clutch seizing leading to no airflow through the radiator

Symptoms of 3.8L overheating:

- High engine temperature warning light

- Steam from the hood or bubbling in the overflow tank

- Low coolant levels and the need for constant top-offs

- Sweet exhaust smell from combustion gases in the cooling system

- Lack of cabin heat with the temperature knob on hot

Effects of overheating:

- Head gasket failure leading to coolant leaks and oil contamination

- Cylinder head warp causing combustion gas or coolant leaks

- Increased internal engine friction and bearing wear

- Piston damage and ring failure

Catching and repairing minor cooling system leaks early is crucial before overheating episodes escalate and ruin the head gaskets or cylinder heads. These embedded engines can cost thousands to repair.

Ticking and Rattling from Rocker Arms and Cam Phaser

A ticking or rattling noise from the valvetrain points to issues with the hydraulic valve lifters, rocker arms or cam phaser on the 3.8L. Here are some specifics:

Rocker arm ticking causes

- Dirty or incorrect viscosity oil leading to stuck rocker arms

- Collapsed lifter unable to maintain zero lash causing valvetrain noise

- Excessive valve guide wear allows oil past the guide into the cylinder

Cam phaser-knocking issues

- Worn cam phaser screen allows debris inside the unit

- Broken cam phaser sprocket bolts rattling around

- Low oil pressure or varnish buildup restricting cam phaser operation

Damage from valvetrain noises

- Accelerated camshaft lobe and rocker’s arm wear from improper contact

- Bent pushrods or valves if rocker’s arms remain stuck open or closed

- Debris kicked up into the valvetrain damaging other components

Diagnosing the specific cause, whether stuck lifters, cam phaser failure or worn rocker arms, takes some mechanical inspection and oil analysis. Replacement of damaged valvetrain components may be needed.

Cracked Cylinder Heads

Cracks in the aluminum cylinder heads emerge on some Jeep 3.8L engines, primarily affecting vehicles with over 100k miles.

How cylinder heads crack

- Repeated overheating episodes weaken the alloy over time

- Over-torqueing head bolts during reassembly warps the flange

- Imperfections within the cast aluminum that expand with heat and age

- Improperly machined head surface causing stress points

Effects of cracked cylinder heads

- Coolant leaks as cracks open up passageways from the head

- Compression loss from gaps between the head and block

- Mixing of engine oil and coolant internally

- Increased potential for head gasket failure

Fixing cracked 3.8L heads

- Welding repairs for minor external cracks by a machine shop

- Replacing the head altogether is necessary if cracks cause overheating or leaks

Unfortunately, even a professionally welded head may eventually crack again. Replacement with a new or used head is the permanent solution.

When is it Time to Repair or Replace the 3.8L?

Given the laundry list of potential malfunctions, knowing when to repair or replace the worn-out 3.8L is key. Here are a few considerations when deciding whether to rebuild or swap the engine:

- Cost of replacement engines – $3,000 to $4,000 with labor for a used engine with reasonable mileage

- Engine rebuild cost – Expect around $4,000+ for a full rebuild done properly

- Compare costs to the vehicle’s overall value if repairs exceed 50% of that value

- Assess how much life is still in the engine; engine swaps often make sense beyond 125k miles

- Consider preventative upgrades during rebuild like forged internals and improved cooling

- Weigh the downtime and cost of frequent repairs against engine replacement/rebuild

In many cases, the 3.8L V6 has exhausted its lifespan once major issues arise. Replacing it with the later Jeep 3.6L or even a 4.0L inline-6 can prove more reliable and cost-effective long term.

Steps to Avoid Future 3.8L Problems

While the 3.8L is prone to problems, diligent maintenance and care can maximize its longevity:

- Stick to 5,000 mile oil change intervals with quality synthetic oil

- Watch for coolant leaks and fix immediately to prevent overheating

- Consider replacing plastic coolant parts with metal components

- Install an auxiliary transmission cooler to reduce operating temperatures

- Upgrade to a heavy-duty radiator and electric cooling fans

- Fix minor leaks early before they lead to oil or coolant depletion

- Consider adding a valve cover PCV “catch can” to reduce oil blowby and sludge accumulation

Even with the best care, the 3.8L hit its limit in many Jeeps after 100k-125k miles. Know when to stop dumping money into repairs and consider a replacement with a more robust engine.

Conclusion – Be Proactive to Avoid Major 3.8L Failures

The 3.8L will go down as one of Jeep’s more troublesome engine choices in an otherwise storied history of reliable powerplants. While proper maintenance and operation can maximize 3.8L life, major issues inevitably occur in many examples.

Stay proactive with preventative maintenance, don’t ignore developing problems, and start budgeting for replacement before major failures leave you stranded. With this guide’s overview of common 3.8L pitfalls, you can now make informed decisions in keeping your Jeep on the road.