Key Takeaways

| Aspect | Detail |

|---|---|

| Repair Complexity | Manual transmissions generally involve simpler repairs than automatics. |

| Repair Costs | Automatic transmissions are typically more expensive to repair. |

| DIY Potential | Manual transmission repairs are more DIY-friendly. |

| Technology | Automatic repairs might require specialized diagnostic tools. |

| Maintenance | Regular maintenance is crucial for both but varies in nature. |

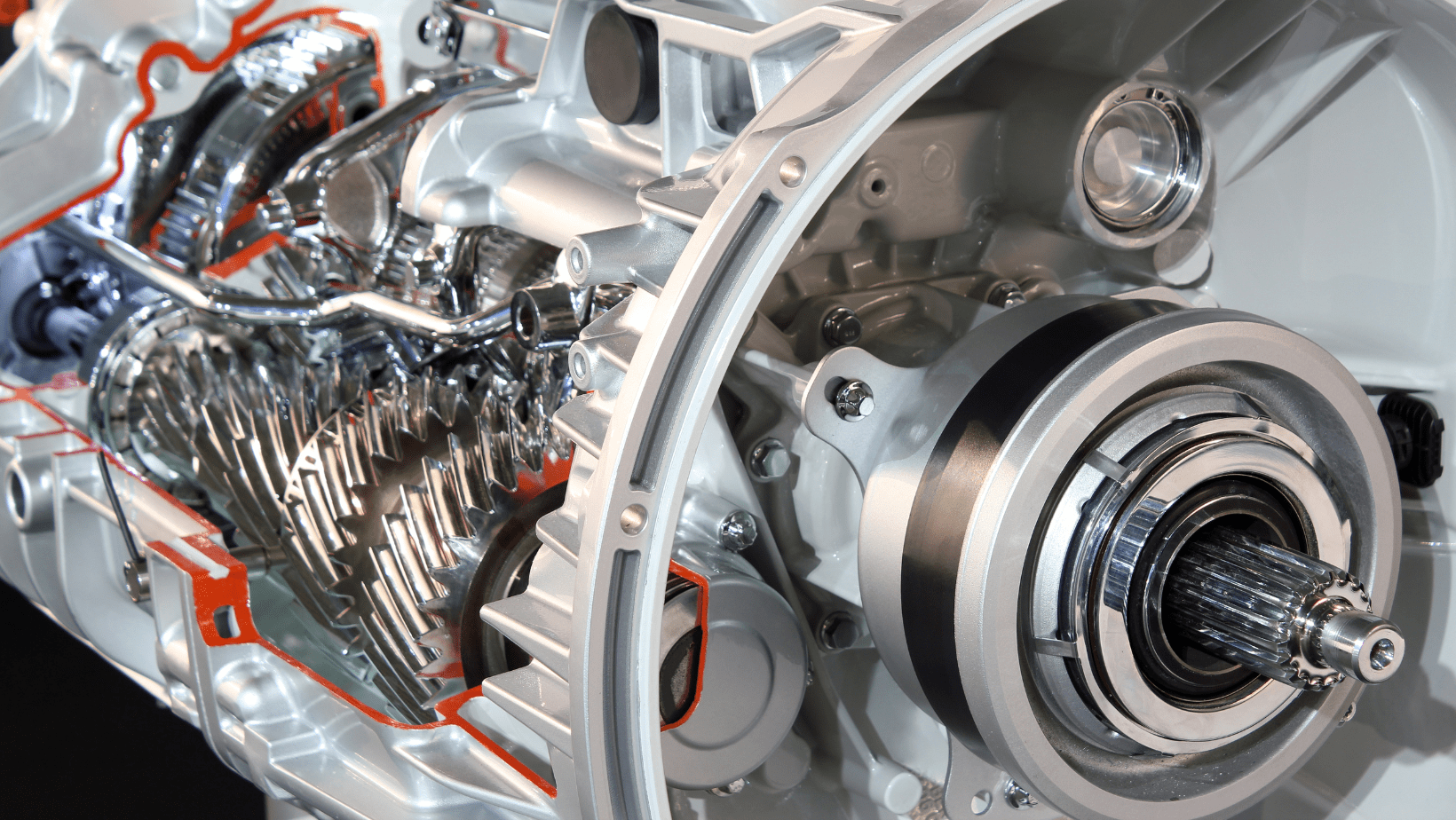

Your vehicle’s transmission is a critical component that ensures the smooth operation of your car, affecting both performance and fuel efficiency. Understanding the nuances between manual and automatic transmission repair can not only save you time and money but also extend the lifespan of your vehicle. This article delves into the intricacies of transmission repair techniques, highlighting the differences between manual and automatic systems.

Manual Transmission Repair

Manual transmissions are often celebrated for their simplicity and durability. The mechanics behind manual transmission repairs are less complex, which translates to more straightforward, and often less expensive, repair jobs. For instance, the clutch is one of the most common manual transmission components to wear out. However, replacing a clutch is a relatively uncomplicated task that can sometimes be within the realm of skilled DIY enthusiasts. Regular maintenance, such as understanding the basics of transmission repair, can prevent severe damage and costly repairs.

Automatic Transmission Repair

In contrast, automatic transmissions are more complex with a multitude of electronic components and hydraulic systems. This complexity means that repairs often require advanced diagnostic tools and specialized knowledge. The cost of repairing an automatic transmission can be significantly higher than a manual one, partly due to the intricacies involved and the need for precision equipment. Ensuring your vehicle undergoes regular checks can mitigate the risks of extensive repairs, as covered in our guide on mastering auto repair safety essential tips.

Manual vs automatic repair: Cost Considerations

When it comes to cost, the type of transmission in your vehicle plays a pivotal role. Automatic transmission repairs can be costly, sometimes prompting car owners to weigh the pros and cons of car repair vs insurance claims. It’s essential to consider the long-term value of the repair against the value of your vehicle.

DIY vs Professional Repair

While some manual transmission issues can be addressed by those with mechanical knowledge, automatic transmission problems are typically best left to professionals. The complexity of automatic systems often requires a level of expertise that goes beyond the average DIY repair.

| Repair Aspect | Manual Transmission | Automatic Transmission |

|---|---|---|

| Complexity | Lower; fewer moving parts | Higher; more components & electronics |

| Diagnostic Equipment | Basic tools often sufficient | Advanced diagnostic tools usually required |

| Repair Costs | Generally lower | Typically higher due to complexity |

| Time for Repair | Can be quicker due to simplicity | Longer repair times due to intricate systems |

| DIY Repair Feasibility | More feasible for those with mechanical skills | Less DIY-friendly; requires specialized knowledge |

| Maintenance Frequency | Regular maintenance needed; less frequent | Regular maintenance is crucial; often more frequent |

| Common Issues | Clutch wear, gear synchronizers | Solenoids, torque converter, transmission fluid |

| Professional Expertise | Specialist not always necessary | Specialist often required for in-depth repairs |

| Longevity | Can last longer with proper care | Longevity varies; can be shorter due to complexity |

| Resale Impact | Fewer repairs can mean higher resale value | Cost of repairs can affect resale value negatively |

This table provides a succinct comparison of the key aspects affecting manual and automatic transmission repairs, offering car owners a clear overview when facing maintenance decisions. It’s crucial to regularly consult with professionals for mastering auto repair safety essential tips to maintain vehicle integrity and performance.

Conclusion about manual vs automatic repair

Regardless of the type of transmission your vehicle has, staying informed about common issues and repair techniques is vital. For example, familiarizing yourself with everything you need to know about brake repairs can provide additional insight into the overall health of your vehicle. Additionally, understanding common car repairs can assist in navigating maintenance and repairs confidently, as discussed in your comprehensive guide to navigating the automotive jungle.