Everything You Need to Know About Brake Repairs

Having properly functioning brakes is absolutely essential for safety when driving. As one of the most used systems in your vehicle, brakes undergo considerable wear over time. This article provides a comprehensive overview of brake anatomy, signs of brake problems, maintenance best practices, and auto brake repair costs.

We’ll cover everything you need to know about auto brake repair including common repairs, replacement parts, and how to maximize brake longevity through proper bedding techniques. Let’s get started!

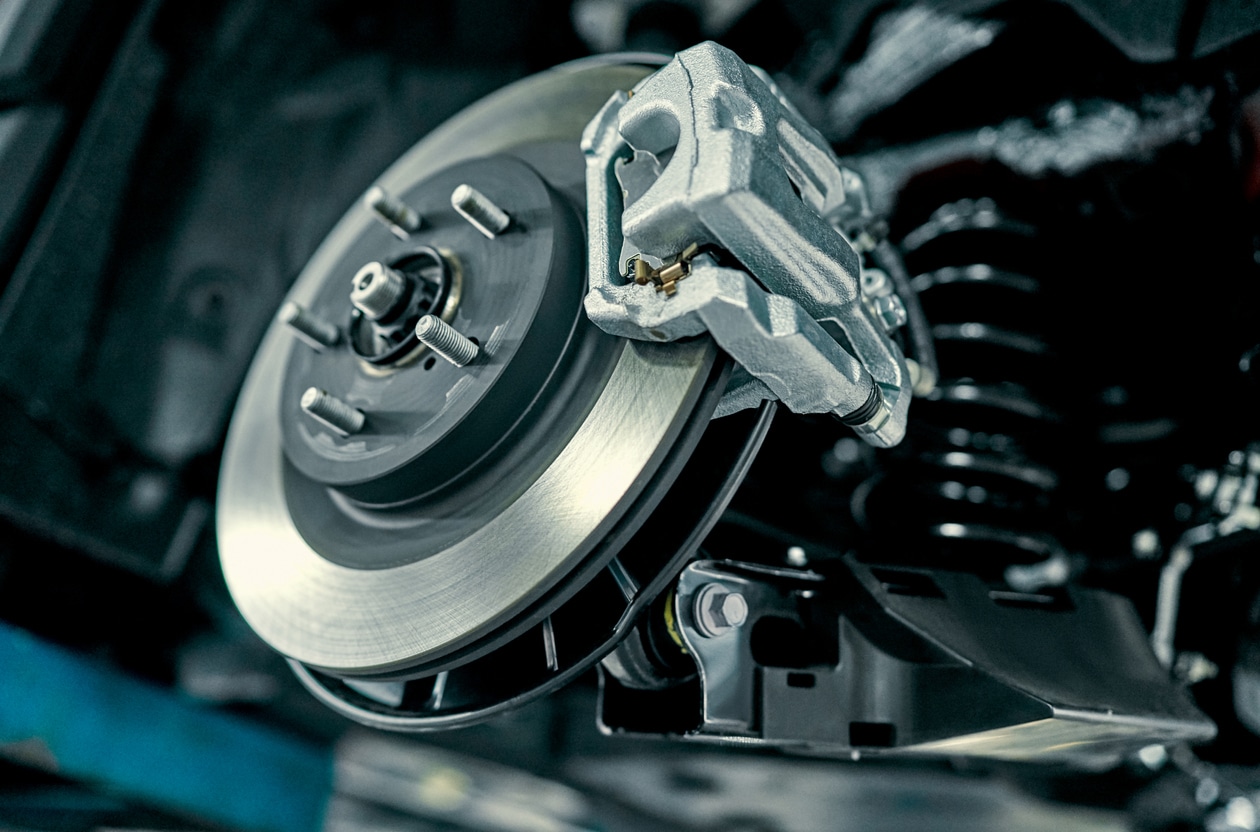

Brake System Components and Operation

Modern automotive brake systems convert hydraulic pressure into stopping power at the wheels. Here are the key components:

Brake Pads

Brake pads are friction material blocks mounted in the caliper that clamp against the rotor surface when braking. Pads compress proportionally to pedal pressure.

Brake Rotors

Rotors are metal discs attached to the wheel hub that the brake pads clamp onto when braking. This friction slows the wheels. Rotors include slots, holes, or curved vanes to dissipate heat and gas.

Brake Calipers

Calipers contain the brake pads and use hydraulic pressure to actuate the clamping motion against the rotors when the pedal is pressed. Calipers include one or more pistons.

Brake Lines and Hoses

These carry pressurized brake fluid from the master cylinder actuated by the brake pedal to the individual wheel calipers. Stainless steel lines with reinforced rubber hoses are used.

Brake Master Cylinder

The master cylinder converts mechanical motion of the brake pedal into hydraulic pressure which is distributed to the brake lines and calipers. It stores reserve brake fluid.

Brake Fluid

Hydraulic brake fluid transmits pedal actuation through the brake lines to the calipers. Fluid must be replaced as it absorbs moisture over time. DOT 3 and DOT 4 grades are common.

Summary of Braking Operation:

- Pressing the brake pedal actuates the master cylinder to pressurize the brake fluid

- Pressurized fluid travels through the lines/hoses to each caliper

- Caliper pistons apply clamping force against the pads compressing them against the rotor

- Friction between pads and rotor slows the wheel and vehicle speed

Now let’s look at common symptoms indicating potential brake problems.

Signs of Brake Issues

Brakes undergo extreme forces and temperatures, so issues will inevitably occur over time. Watch for these signs of brake problems:

| Symptom | Likely Cause |

|---|---|

| High-pitched squealing while braking | Worn out brake pads with low friction material |

| Grinding noises under braking | Excessively worn pads damaging rotors |

| Brake pedal pulsation | Warped rotors failing to brake smoothly |

| Vehicle pulling under braking | Uneven pad deposition from stuck calipers |

| Increased stopping distance | Worn pads/rotors provide less friction |

- Brake squeal – High-frequency squealing while braking signals worn pads with minimal friction material left. Squeals often oscillate as you continue braking. Address promptly before pads wear down to backing plates.

- Grinding – Deep screeching and grinding indicates pads worn so thin that metal backing plate is now contacting rotors. This damages rotors. Have pads and rotors inspected.

- Pulsating pedal – A pulsating brake pedal points to warped rotors that fail to contact pads evenly. Resurfacing or replacing rotors is required.

- Pulling – If the vehicle pulls left or right under braking, sticky slider pins may prevent caliper pistons from retracting evenly. Lubricate and service calipers.

- Longer stopping distance – Worn pads and rotors provide less friction requiring more pedal travel distance to stop. Replace immediately.

Address any brake symptoms promptly before further damage or hazardous brake failure occurs. Now let’s look at common maintenance and auto brake repair.

Common Brake Maintenance and Repairs

This section covers typical brake servicing, worn parts replacement, and repairs needed over a vehicle’s lifetime to keep the brakes operating safely.

Routine Brake Maintenance

Performing regular brake maintenance maximizes the system’s lifespan:

- Fluid flushes – Brake fluid absorbs moisture eventually requiring complete flushes. Flush fluid every 2 years as basic preventative maintenance. Use fresh DOT 3 or DOT 4 grade fluid.

- Lubrication – Lubricate caliper slides and pins occasionally to prevent sticking and ensure even pad wear. Use high temperature brake lubricant.

- Hose inspection – Rubber brake hoses age and crack internally. Inspect for any swelling or surface cracks during oil changes.

Proper fluid replacement and lubrication reduces corrosion and keeps components moving freely.

Brake Pad and Rotor Replacement

As friction surfaces, brake pads and rotors gradually wear down with use requiring replacement:

| Part | Replacement Interval |

|---|---|

| Brake pads | 30,000 – 70,000 miles |

| Rotors | 60,000 – 100,000 miles |

- Inspect pad thickness during tire rotations or oil changes. Most pads have wear limit grooves.

- Resurface or replace rotors when pads are swapped to restore a smooth friction surface.

- Quality ceramic pads offer enhanced stopping power and low dust.

- Drilled/slotted rotors improve heat dissipation and pad grip.

Brake Caliper Repair and Replacement

Brake calipers contain cylinders with pistons that often seize over time due to corrosion. Repairs include:

- Lubricating caliper pins and bushings to prevent sticking

- Replacing the caliper if piston or seal damage occurs

- Rebuilding calipers by honing bores and installing new seals and piston kits

Sticking calipers drag pads causing rapid wear and uneven braking.

Brake Line and Hose Replacement

Rubber brake hoses expand internally over time eventually splitting. Replace any bulging, cracked, or seeping hoses:

- Rubber hoses should be replaced every 4-5 years as basic preventative maintenance.

- Stainless steel brake lines are more durable only needing replacement if visibly cracked or leaking.

- Ensure proper installation position and torque when changing brake lines and hoses.

Master Cylinder and Booster Repair

The brake master cylinder and booster require rebuilding or replacement if:

- Brake pedal sinks to floor indicating fluid loss

- Master cylinder leaks externally

- Brake booster fails to provide proper vacuum assist

These hydraulic components actuate the entire brake system.

Brake Fluid Flush and Bleeding

A brake fluid flush and bleed is required when:

- Flushing old contaminated fluid from the system

- Replacing any hydraulic components

- Brake lines were opened up breaking the closed loop

Bleeding removes air bubbles from lines and calipers for solid pedal feel. Use a brake bleeder tool for clean fluid flushes.

Bedding in New Brake Pads and Rotors

Fresh pads and rotors require proper break-in to transfer material evenly and avoid glazing:

| Bedding-In Tips |

|---|

| Accelerate to moderate speed and brake firmly 10-20 times |

| Allow components to fully cool between intervals |

| Avoid aggressiveness and heat for 500-1000 miles |

| Don’t come to complete stops during break-in |

Gradual break-in procedures ensure maximum performance, life, and safety from new brake components.

Now that we’ve covered common servicing let’s discuss costs.

Brake Repair Costs and Pricing

Auto Brake repair costs vary based on the specific parts and labor needed:

| Brake Repair | Typical Cost |

|---|---|

| Brake Pad Replacement | $150 – $250 per axle |

| Brake Rotor Resurfacing | $150 – $200 per axle |

| Brake Caliper Replacement | $200 – $400 each |

| Brake Fluid Flush | $70 – $150 total |

| Brake Line or Hose Replacement | $100 – $200 per line |

| Brake Master Cylinder Replacement | $350 – $550 |

| Full Brake Caliper and Line Replacement | $800 – $1500 |

Labor costs make up a considerable portion of brake repair expenses. Quality components and proper bedding-in provides maximum value from new parts investments.

With this overview of brake anatomy, maintenance, repairs, and pricing you now have a solid understanding of your vehicle’s brake system. Listen for any symptoms of issues arising promptly. Stay safe!

[…] Use the Right Parts: Quality matters. Opt for trusted brands and proven brake components. […]

[…] Don’t overlook the importance of a clean, flat workspace. Refer to our comprehensive guide on everything you need to know about brake repairs, as the methodology for preparation shares […]

[…] Everything You Need to Know About Brake Repairs […]