Key Takeaways of cold air intake materials

| Aspect | Key Point |

|---|---|

| Material Types | Exploring different materials used in cold air intakes |

| Performance Impact | How materials affect intake efficiency and vehicle performance |

| Durability | Analysis of material longevity and resistance to elements |

| Aesthetic Appeal | The role of materials in the visual aspect of intakes |

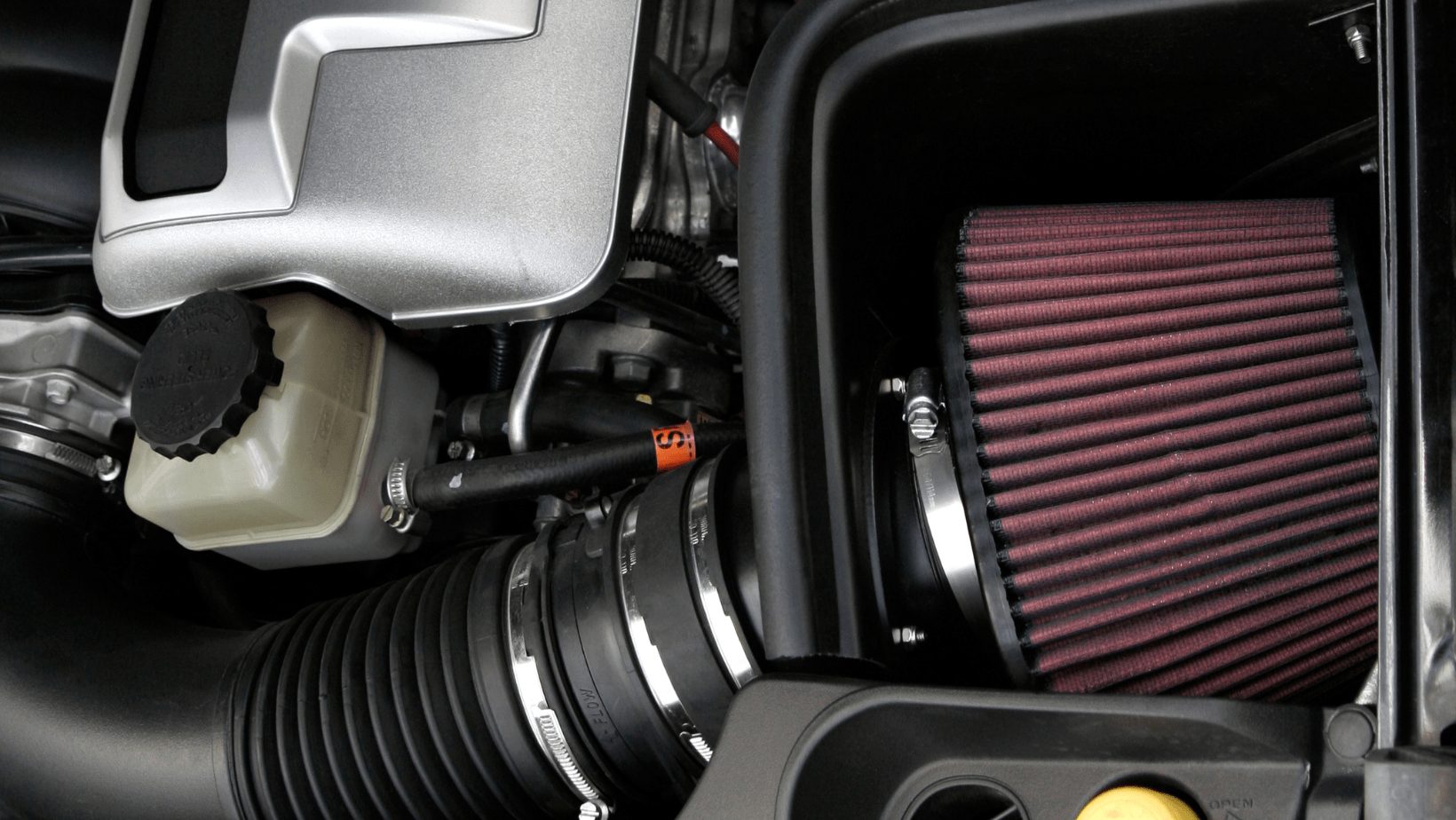

When it comes to upgrading your vehicle’s performance, the choice of materials for a cold air intake system plays a pivotal role. Cold air intakes are essential for increasing engine efficiency and power, but the material they are made from can significantly impact their effectiveness and longevity.

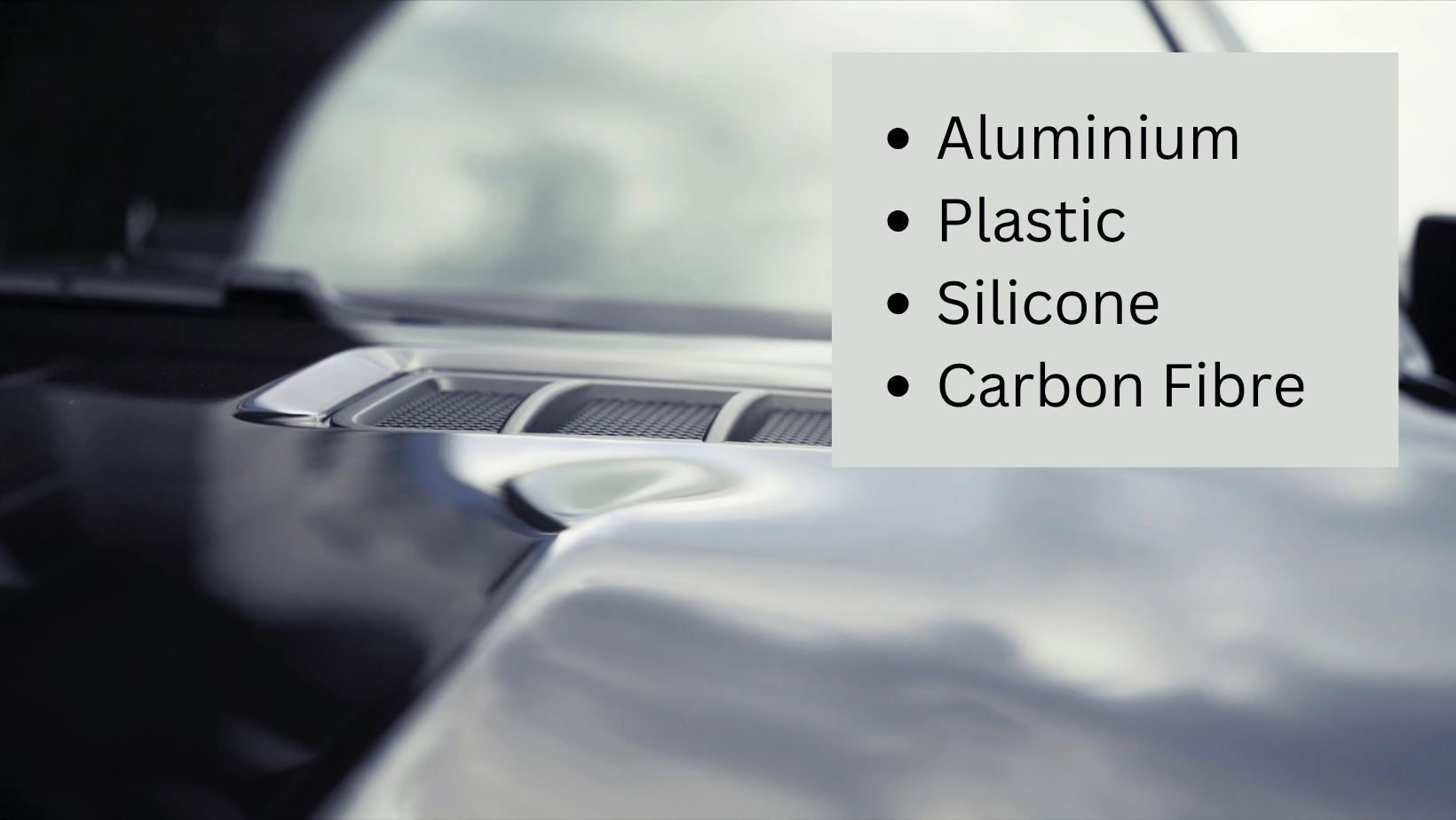

Variety of Materials in Cold Air Intakes

Cold air intakes are commonly made from materials like aluminum, plastic, silicone, and carbon fiber. Each of these materials has unique properties that affect the intake’s performance.

- Aluminum: Known for its durability and heat resistance, aluminum intakes can improve engine responsiveness. However, they may be heavier than other options.

- Plastic: Light and cost-effective, plastic intakes are popular for their ease of installation and minimal heat conductivity.

- Silicone: With excellent heat resistance and flexibility, silicone intakes reduce heat soak and improve airflow.

- Carbon Fiber: This high-end material is favored for its strength, lightweight properties, and aesthetic appeal. It’s ideal for performance-oriented drivers.

Impact on Performance and Efficiency

The choice of material not only affects the durability of the cold air intake but also plays a crucial role in its efficiency. For example, materials like carbon fiber and silicone are excellent for reducing heat soak, a common issue that can decrease engine performance.

Aesthetic and Practical Considerations

While performance is paramount, the aesthetic appeal of the cold air intake material shouldn’t be overlooked. Materials like carbon fiber offer a sleek, high-performance look that many car enthusiasts appreciate.

Material Longevity and Maintenance

Durability is a key factor in choosing the right material. Aluminum and carbon fiber are known for their long lifespan, while plastic and silicone might require more frequent checks and maintenance.

| Material | Properties | Best Suited For | Maintenance |

|---|---|---|---|

| Aluminum | Durable, heat resistant, heavier | High performance, responsiveness | Low maintenance, long-lasting |

| Plastic | Light, cost-effective, minimal heat conductivity | Ease of installation, general use | Regular checks needed, less durable |

| Silicone | Heat resistant, flexible, reduces heat soak | Reducing heat soak, flexible setups | Durable, occasional maintenance |

| Carbon Fiber | Strong, lightweight, aesthetically pleasing | High-end vehicles, performance focus | Low maintenance, very durable |

Choosing the Right Material for Your Vehicle

Your choice should be guided by your vehicle’s specific needs and your performance goals. For instance, if you own a Honda Civic, you might prioritize a lightweight material like plastic, while a 6.6 Duramax engine could benefit more from the durability of aluminum.

Comprehensive Understanding of Cold Air Intakes

To make an informed decision, it’s crucial to understand all aspects of cold air intakes. Explore articles on basics of cold air intakes and cold air intake tuning for a deeper dive into this subject.

Conclusion and Further Learning

Choosing the right material for your cold air intake is a balance between performance enhancement, durability, and aesthetic preference. By understanding the unique properties of each material, you can make an informed decision that best suits your vehicle and driving needs.

Explore more on this topic through our detailed guides on cold air intake benefits and the impact of cold air intakes on engine longevity.