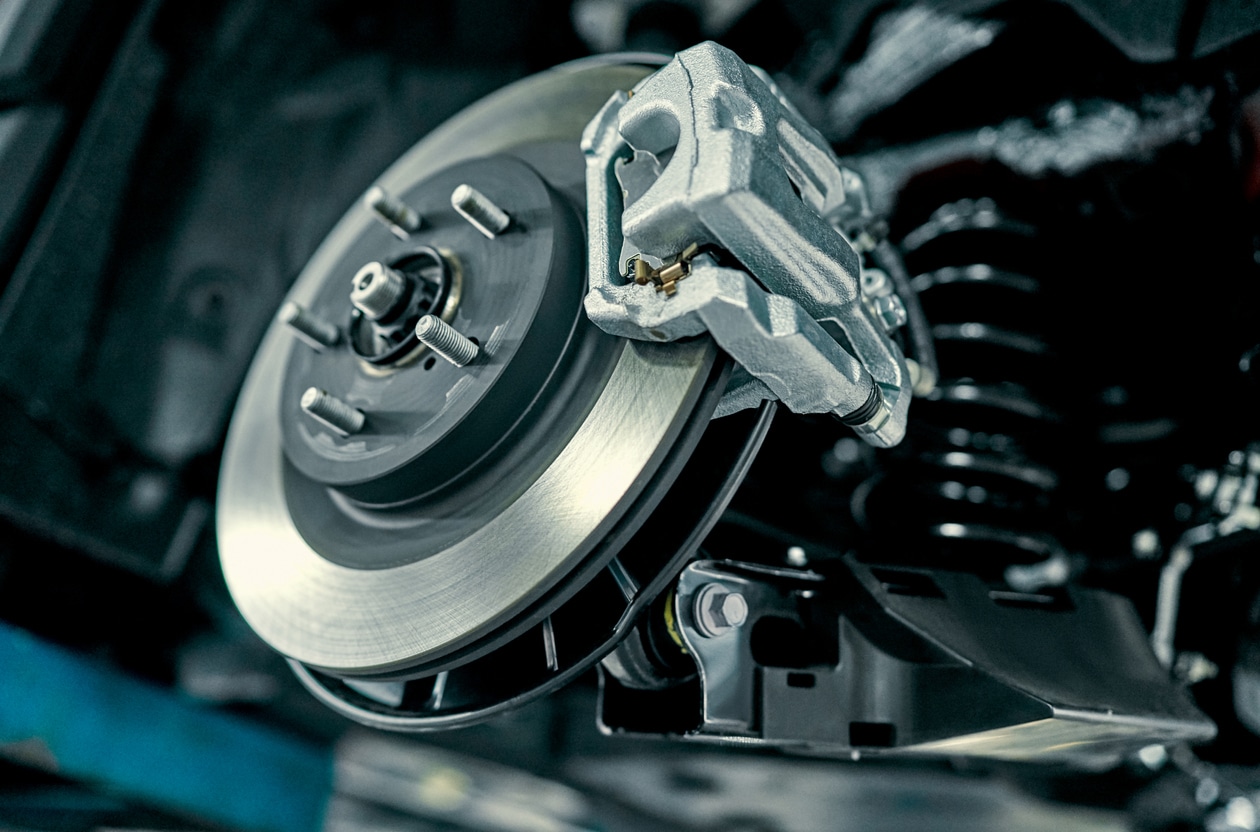

Tips to Ensure Optimal Brake Performance

Brakes are one of the most important components of your vehicle, as they allow you to slow down and stop safely. However, brakes can wear out over time and lose their effectiveness, which can compromise your safety and performance. Therefore, it is essential to follow a brake maintenance schedule and take care of your brakes regularly. In this article, we will share some tips on how to improve your braking performance and extend the life of your brake system.

Key Takeaways:

- Follow a brake maintenance schedule that includes inspecting the brake pads, rotors, calipers, fluid, and lines every 12,000 miles or 4-6 months, and replacing them when necessary.

- Bed in your new brakes by performing several hard stops from moderate and high speeds to transfer pad material to the rotors and improve friction.

- Avoid brake rubbing by centering the calipers over the rotors and checking for any signs of wear, damage, or rust on the brake components.

- Upgrade your brake system with larger, slotted, or cross-drilled rotors, bigger or multi-piston calipers, high-performance brake pads, and stainless steel brake lines for better heat dissipation, stopping power, and modulation.

- Use the correct braking technique by applying firm and progressive pressure on the brake pedal, and avoiding sudden or prolonged braking that can overheat and damage the brakes.

Brake Maintenance Schedule

The first step to ensure optimal brake performance is to follow a brake maintenance schedule that suits your vehicle and driving style. A brake maintenance schedule is a set of guidelines that tell you when and how to inspect, service, and replace your brake components. By following a brake maintenance schedule, you can prevent brake problems, improve your safety, and save money on repairs.

A brake maintenance schedule typically includes the following tasks:

| Task | Frequency | Purpose |

|---|---|---|

| Inspect the brake pads | Every 12,000 miles or 4-6 months | To check the thickness and condition of the friction material, and replace the pads when they are less than 4mm thick or show signs of uneven wear, cracking, glazing, or contamination. |

| Inspect the brake rotors | Every 12,000 miles or 4-6 months | To check the surface and thickness of the discs, and replace or resurface the rotors when they are below the minimum thickness, warped, scored, cracked, or rusted. |

| Inspect the brake calipers | Every 12,000 miles or 4-6 months | To check the operation and condition of the calipers, and replace or rebuild the calipers when they are leaking, seized, corroded, or damaged. |

| Inspect the brake fluid | Every 12,000 miles or 4-6 months | To check the level and quality of the brake fluid, and replace the fluid when it is low, dirty, contaminated, or old. |

| Inspect the brake lines | Every 12,000 miles or 4-6 months | To check the integrity and condition of the brake lines, and replace the lines when they are leaking, cracked, kinked, or corroded. |

You can perform some of these tasks yourself, or take your vehicle to a professional mechanic for a brake inspection and service. You can also consult your owner’s manual or manufacturer’s website for the specific brake maintenance schedule and recommendations for your vehicle model and year.

Brake Performance Tips

Besides following a brake maintenance schedule, you can also improve your braking performance by applying some tips and tricks that can enhance your brake system and your braking technique. Here are some of the most effective ways to boost your brake performance:

Bed in your new brakes

If you have installed new brake pads or rotors, you need to bed them in before you can enjoy their full potential. Bedding in is a process of breaking in the new brake components by performing several hard stops from moderate and high speeds. This transfers some pad material to the rotors and creates a thin and uniform layer of friction that improves the braking efficiency and reduces noise and vibration. To bed in your new brakes, you can follow these steps1:

- Accelerate the vehicle to a moderate speed (about 40 mph) and then firmly apply the brakes until you are at walking speed. Repeat this process 20 times.

- Accelerate the vehicle to a faster speed (about 60 mph) and then firmly apply the brakes until you are at walking speed. Repeat this process 10 times.

- Drive the vehicle for at least 15 minutes without using the brakes to allow them to cool down.

- Avoid coming to a complete stop or locking the wheels at any point during this process.

Avoid brake rubbing

Brake rubbing is a common issue with disc brakes, where the brake pads touch the rotors slightly even when the brakes are not applied. This causes unwanted friction, noise, and heat that can reduce your brake performance and lifespan. To avoid brake rubbing, you can try these tips1:

- Center the calipers over the rotors. To do this, loosen the caliper bolts, spin the wheel, then with the brake lever applied, tighten the bolts. This should align the calipers with the rotors and eliminate any rubbing.

- Check for any signs of wear, damage, or rust on the brake components. If the pads, rotors, or calipers are worn out, warped, cracked, or corroded, they may cause brake rubbing and need to be replaced.

- Clean the brake components regularly. Dirt, dust, oil, or grease can contaminate the brake pads and rotors and cause brake rubbing and squealing. You can use a brake cleaner spray and a soft cloth to remove any dirt or residue from the brake components.

Brake maintenance schedule: Upgrade your brake system

If you want to take your brake performance to the next level, you can consider upgrading your brake system with some aftermarket parts that can improve your braking power, modulation, and heat dissipation. Some of the most popular brake upgrades are:

- Larger rotors. Larger rotors have more surface area and leverage, which means they can generate more braking force and dissipate more heat. Larger rotors are especially beneficial for heavy vehicles or high-speed driving.

- Slotted or cross-drilled rotors. Slotted or cross-drilled rotors have grooves or holes on the surface that help to vent the gas and dust that can build up between the pads and rotors. This can improve the contact and friction between the pads and rotors, and reduce the brake fade and noise.

- Bigger or multi-piston calipers. Bigger or multi-piston calipers have more clamping force and better distribution of pressure on the pads and rotors. This can improve the responsiveness and consistency of the brakes, and reduce the brake pad wear and distortion.

- High-performance brake pads. High-performance brake pads have a higher coefficient of friction and a wider operating temperature range than the stock pads. This can improve the stopping power and fade resistance of the brakes, and reduce the noise and dust. However, high-performance brake pads may also wear out faster and be more expensive than the stock pads.

- Stainless steel brake lines. Stainless steel brake lines are more durable and resistant to expansion than the rubber brake lines. This can improve the brake pedal feel and feedback, and reduce the brake line pressure loss and fluid contamination.

| Upgrade | Pros | Cons |

|---|---|---|

| Larger rotors | More braking force and heat dissipation | More weight and cost |

| Slotted or cross-drilled rotors | Better contact and friction | More prone to cracking |

| Bigger or multi-piston calipers | More responsiveness and consistency | More complex and expensive |

| High-performance brake pads | More stopping power and fade resistance | More wear and cost |

| Stainless steel brake lines | More pedal feel and feedback | More difficult to install |

Use the correct braking technique

The final tip to ensure optimal brake performance is to use the correct braking technique that suits your driving conditions and style. The correct braking technique can help you to control your speed, avoid skidding, and save your brakes from unnecessary wear and damage. Here are some of the best practices for braking:

- Apply firm and progressive pressure on the brake pedal. This means that you should start with a light pressure and gradually increase it until you reach the desired braking force. This can help you to modulate your braking and avoid locking the wheels or activating the anti-lock braking system (ABS).

- Avoid sudden or prolonged braking. Sudden or prolonged braking can overheat and damage your brakes, and reduce their effectiveness and lifespan. You should try to anticipate the traffic and road conditions, and brake smoothly and gently whenever possible. You should also avoid riding the brakes or using the brakes to maintain your speed downhill, as this can cause unnecessary friction and heat. Instead, you should use the engine braking or lower gears to slow down your vehicle.

- Use the threshold braking technique. Threshold braking is a technique of applying the maximum braking force without locking the wheels or activating the ABS. This can help you to stop your vehicle in the shortest distance and time possible, and maintain some steering control. To perform threshold braking, you should apply firm and progressive pressure on the brake pedal until you feel the wheels start to lock, then slightly release the pressure to keep the wheels rotating, and repeat this process until you stop. This technique requires some practice and skill, and may not be necessary if your vehicle has ABS.