Best Silverado 5.3 turbo kit: The Best Turbocharger for 5.3 vortec

Most automobile racing cars and off-road vehicles have benefitted from the invention, and drivers claim that pressing on the gas pedal now requires less effort than before with higher speeds compared to the original vehicle engine design.

While some jurisdictions, such as California, have banned the kits due to health concerns, they are still allowed in racing automobiles and off-road trucks. According to experts, using this kit correctly produces outstanding results. Others feel that the kit is ideal for a vehicle you don’t plan on keeping for long.

We’ve compiled a list of the most essential facts about turbocharging your car that you should know before you buy.

This blog post explores the finest Silverado turbo kits available on the internet, as determined by our research. They use high-quality materials to provide you with dependable service for a long time. We also took into account the power output so that you could get a turbo kit that can help your vehicle accelerate in new ways.

We offer a wide range of turbo kits for both novices and experts. Users with little experience will select entry-level options, while those with more expertise will go for high-performance screamers. Regardless, you will be able to choose the best turbo kit for your vehicle.

When you shop on the internet, you may run into problems while making a purchase since there are numerous operations accessible to you in many online shops. This is where our assistance comes in handy.

Take a look at our top six choices to see which one is best for your automobile. You’ll also get a buying guide as well as an overview of some of the most frequently asked issues. Continue reading to discover what each Silverado Turbo Kit has to offer.

- At maximum effort, it delivers 900hp

- Versatile for various engine types

- It’s an upgraded type with new features

- Value for money: 🔥🔥🔥🔥🔥

- Purchase link: Buy your Turbo Kit T4 Silverado Sierra Turbocharger Vortec V8 LS 4.8 5.3 6.0 99+ at Amazon!

- Boosts engine horsepower

- CNC mandrel-bent tubing design

- Highly compatible with Silverado and Sierra

- Easy to install as the guideline is available

- Value for money: 🔥🔥🔥🔥

- Purchase link: Buy your LSx 1000HP Chevy Twin Turbo Kit Turbocharger v8 LS1 LS2 LS6 LS7 Vband Ls Vortec at Amazon!

- Value for money: 🔥🔥🔥🔥

- Purchase link: Buy your New Universal T3 T4 T3/T4 T04E Turbo Charger Turbocharger Kit Stage III 350HP Upgrade at Amazon!

- Value for money: 🔥🔥🔥🔥

- Purchase link: Buy your FULL Hotparts Turbo T4 Kit Vortec V8 LS 4.8 5.3 6.0 6.2 Silverado Sierra LSX 3" at Amazon!

- Value for money: 🔥🔥🔥🔥

- Purchase link: Buy your Turbo Kit T70 Single T4 Silverado Turbocharger Vortec 5.3 at Amazon!

- Value for money: 🔥🔥🔥🔥

- Purchase link: Buy your Single Turbo Hotparts Kit Turbocharger Vortec V8 LS 4.8 5.3 6.0 Silverado Sierra at Amazon!

- Value for money: 🔥🔥🔥🔥

- Purchase link: Buy your Vortec LS Single T4 Turbo Kit Complete Silverado Sierra Turbocharger V8 LS 4.8 5.3 6.0 62 at Amazon!

What is a Turbocharger?

Induction can be accomplished in a variety of ways. Superchargers use internally driven turbines or fans driven by the engine’s current pulley system, which draws power from the engine. Turbochargers function similarly to superchargers in that an internal fan is used to create a boost. Turbines inside are not spun by a pulley like superchargers; rather, they spin on exhaust produced by the engine and another turbine mirrored on the intake side draws air into the system, generating boost.

The Vortec engine in the Sierra is a naturally aspirated gasoline engine. It relies on a vacuum produced by the intake stroke of the pistons to draw air in. The issue is that they can only intake as much air as there is available to them. This causes an engine to draw in a percentage of air volume, preventing it from working with 100 percent of its displacement due to atmospheric pressures and other natural factors.

A turbocharger does this by forcing air into the chambers of the engine. The pressurized system is intended to bring the engine up to and beyond 100% power. This also aids in ensuring that the cylinders’ compression ratios count for more. Both factors working together will boost horsepower considerably.

Best Overall

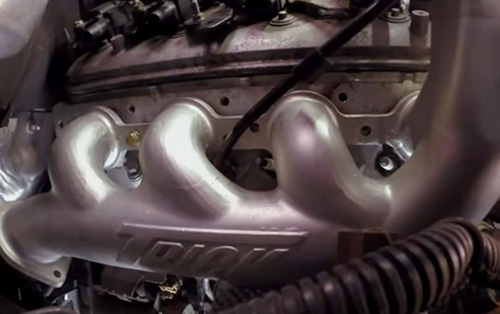

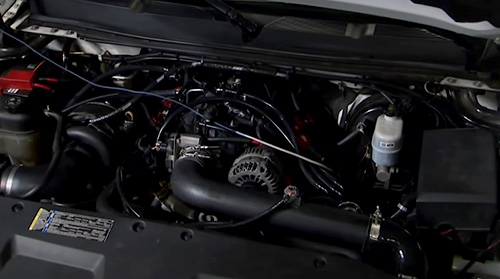

MMI GM VORTEC TWIN TURBOCHARGER KIT PACKAGE CHEVY GM 5.3L

If you had a simple turbo system that lets you to put together in minutes, it would be the start of a stress-free existence and an exciting moment. The good news is that this MMI GM Vortec Twin Turbocharger Kit is everything you need in a do-it-yourself product.

It comes with instructions for installation. The manufacturer provides clear instructions so that you can follow them without difficulty. Then you’ll immediately start using the device to see if it works on the road.

GM 4.8l 5.3l 6.0l Vortec Twin Turbocharger Kit Package is an OEM-grade upgrade that will give your Chevy GM 4.8l 5.3l 6.0l unrivaled power and dependability without the interference of other manufacturers’ components – guaranteed! For all of those major project demands, you can get good durability at a fair price! The GM 4.8L 5.3L 6.0L MMI Vortec Twin Turbocharger Kit Package is the most comprehensive kit for your engine bay available! With easy-to-follow instructions straight from our team of race engineers, you can rapidly and simply improve horsepower and torque with this high-quality turbocharger kit package built specifically for your new or favorite car’s requirements!

The Focus ST comes with OEM-level cast exhaust manifolds and downpipes, which are both high-quality components. These will assist in keeping the turbo system debris-free, resulting in improved efficiency.

The lightweight and long-lasting TIG-welded aluminum intake piping available is ideal for drag racers. You won’t add much weight to your engine; instead, the sleek and light aluminum construction will give you a smooth and lightweight experience.

Furthermore, the bar and plate front-mount intercooler will be part of your system, ensuring that it continues to operate well even if the high temperatures and pressure overwhelm it.

The turbo system’s SST-100S V1 is designed to work on any petrol engine from 1.7 liters up to 4 cylinder gasoline engines as well as diesel engines with a displacement of three liters and greater. The complete braided SS -AN oil lines drain through the movable parts of the turbo system, improving efficiency and lowering gas intake.

Turbo Kit T4 Silverado Sierra Turbocharger Vortec V8 LS 4.8 5.3 6.0 99+

LSx 1000HP Chevy Twin Turbo Kit Turbocharger v8 LS1 LS2 LS6 LS7 Vband Ls Vortec

New Universal T3 T4 T3/T4 T04E Turbo Charger Turbocharger Kit Stage III 350HP Upgrade

FULL Hotparts Turbo T4 Kit Vortec V8 LS 4.8 5.3 6.0 6.2 Silverado Sierra LSX 3"

Turbo Kit T70 Single T4 Silverado Turbocharger Vortec 5.3

Single Turbo Hotparts Kit Turbocharger Vortec V8 LS 4.8 5.3 6.0 Silverado Sierra

Vortec LS Single T4 Turbo Kit Complete Silverado Sierra Turbocharger V8 LS 4.8 5.3 6.0 62

5.3L Vortec 5300 Reliability

Let’s start by discussing engine dependability. The Vortec 5.3 is highly regarded as a long-lasting engine, with the majority of engines lasting 200k to 300k miles before needing to be replaced. With nearly no engine issues throughout ownership of a Suburban with the LM7 engine, it has been the most cost-effective.

On these vehicles, the engine blocks are nearly indestructible. You’ll almost certainly need to replace some basic components throughout the car’s life, including the water pump, plugs and coils of course, as well as gaskets and hoses. Overall, the engine block is quite sturdy and rarely causes issues.

How much HP can you get out of a 5.3 Vortec

It all depends on how much money you’re willing to spend on your 5.3 Vortec. You may acquire 1000 HP by upgrading your turbo, intercooler, heads, cam, and forged cranks if you are prepared to make modifications. If you don’t mind spending a little extra, you may get 500 HP with just a few modifications.

What Is The Difference Between Stock And Modified? This experiment compares the stock and modified versions of the 5.3L V8 to see how much power we’d gain if we boosted the situation. The 5.1L in basic form was run using a single S480 turbocharger. The supercharged 5.2L generated 532 horsepower at 5,500 rpm and 555 lb-ft torque at 4,700 rpm when equipped with a similar turbo system. The stock combination’s power jumped to 801 hp at 7,000 rpm, and 616 lbft torque was achieved at 5,600 rpm. Despite the same wastegate settings, the boost on the modified combination increased to 11.9 psi. The modifications resulted in a 169-hp gain.

Although the question was simple, finding the answer necessitated four engine configurations. We’d start with a stock 5.3L engine, which was effectively identical to the stock vehicle. Next, we’d run the test in naturally aspirated mode and then again with a single turbo system. Finally, we replaced the camshaft, cam, intake manifold, and cylinder heads with aftermarket versions before repeating the tests with both naturally-aspirated and turbo systems. We were able to compare how much power each version increased. Although the cam was not designed for turbo applications, it raised the stock engine’s horsepower by 118.

Chevy 5.3 Vortec Models

This chart compares the 5.3L V8 in the 2016 Chevy Silverado to other engines. Regular unleaded gasoline produces 355 horsepower at 5,600 rpm and 383 pound-ft at 4,100 rpm. The Max Towing Package is standard on this model, which includes 2WD and the maximum towing capacity. This is the first time we’ve put a V8 with an 8-speed automatic transmission into testing. The Silverado 2016 model year introduces a new connection option. It’s only available in more expensive trim levels. The 2019 Chevy Silverado 1500 has a 5.3L V8 with six speeds automatic transmission that gets 15/21/17 mpg (Dynamically Fueled – DFM) and a 5.0L V6 with eight speeds automated gearbox that achieves 17/23/19 mpg (Dynamically Fueled – DFM).

Although the L83 name is perhaps unknown to the younger segment of our hobby, it refers to the 5.3L direct-injected, direct injection 5.7L power plant. It was utilized on Corvettes from 1982 through 1984. There was no Corvette available in 1983 owing to a GM cross-fire injection system with a unique, cross-ram intake design that delivered two single-hole throttle bodies. The L98 Tuned-Port motors in the ’80s and early ’90s were derived from the L83 xfire, which was rated at 205 horsepower in 1984. The original 205-hp L83 is not particularly revered by Chevrolet fans. The new gen-5 L83, on the other hand, may alter that. It will never be able to outshine other alpha-numeric legends such as the DZ302, L88, LS6 or LS6.

The vehicle’s original V8 engine is a 5.3-liter V8. The stock horsepower level has not changed. GM has secured the ECU/computer of the new truck, preventing aftermarket firms from boosting power.

It’s mated to an 8-speed automatic transmission as well. The little V8 engine can now be coupled with the 8-speed gearbox. The V8 small engine is now compatible with an auto gearbox for the first time in its history. These trims and vehicle are both part of the Limited trim level, which means that they have all of the bells and whistles that come standard on higher trims.

How to Choose Best Silverado Turbo Kit

Adding a Silverado turbo boost to your current engine is a wonderful idea if you want to improve torque. We’ve provided you with the top six options anytime you’re having trouble deciding what to do.

We’ll go through a few factors to think about before you buy it in this section. Continue reading to learn how to pick the finest unit for you.

Quality

The first and most important thing to look for when purchasing a turbo kit is the materials. You’ll need a kit that will last you a long time once you install it. This is why the construction of the kit is so crucial. Steel and aluminum are two excellent materials for durability, therefore we recommend them.

Complete Kit

Do you want to buy additional accessories or a complete kit? This is yet another issue. Some producers will not provide you with a full kit. You’ll have to get other accessories for a good fit. For you, this becomes an issue.

Prices

This is one of the most important elements to consider. Check to see whether your budget allows you to make the selection. If so, go ahead and acquire it. If not, explore other possibilities for your needs.

Warranty

The warranty provides you peace of mind when purchasing a turbo kit and putting it to use. This is due to the fact that the manufacturer offers protection for you in the event of an issue. You must also contact their customer care to determine if they are helpful.

Turbocharger Accessories

A turbocharger alone will only help to boost engine output. Even with a modest boost, you may anticipate a tremendous amount of power. Increased efficiency and power output, on the other hand, will always be a priority. There’s always the choice of boosting the system by adding larger turbos; however, there are add-ons that can be utilized to improve your current setup for Best Silverado 5.3 turbo kit.

Blow off Valve

Turbos compress air. Air that is pressurized is harmful to mechanical components and, if not properly maintained, may be deadly. As the RPM of the turbocharger rises, it will have a defined amount of pressure in the system that will continue even after the throttle is shut off. If there is enough pressure in the system due to a blow-off valve being closed when the throttle is released, it can cause damage to the turbocharger. Once you’ve stopped accelerating by releasing your foot from the accelerator pedal, this excess pressure goes away so you don’t have any problems with your vehicle’s performance.

Intercooler

The purpose of an intercooler is to cool the compressed air in a turbocharging system. An intercooler, like a radiator, works to fulfill the same objectives as a cold air intake on a naturally aspirated engine. Best Silverado 5.3 turbo kit.

Boost Controllers

Boost does create power, but too much of it can be harmful to an engine. Too much might harm internal components and cause chamber detonation. Boost controllers regulate the amount of pressure in the turbocharging intake manifold and provide users with control over their systems.

Conclusion

A turbo boost is the answer if you want to get the most out of your sluggish engine. We’ve come across equipment and engines that have been modified with turbo kits. Torque does increase, and you receive a more powerful machine than previously. The productivity of labor improves as a result of this.

We’ve compiled a list of the best Silverado turbo kits for your convenience. We spent a lot of time evaluating the kit’s quality and completeness in our reviews. We even investigated how well it worked overall. All these are done with the goal of obtaining the finest turbo kit for the money.

Based on your budget, you can pick the one that fits your needs and ranks among those who breathe fire.

[…] boost, enabling cars to achieve incredible speeds. For instance, for those driving a Chevrolet, the Silverado 5.3 Turbo Kit and the Chevy 4.3 V6 Turbo Kit are game changers. But remember, with great power comes great […]

[…] usage. To delve deeper into this topic, you might want to explore specific kits such as the Silverado 5.3 turbo kit or the best supercharger for a 6.2 Silverado, or even consider a comprehensive guide like the […]

[…] choices, such as a Silverado 5.3 turbo kit, can make a significant difference. These kits are designed to maximize performance while […]